Introduction

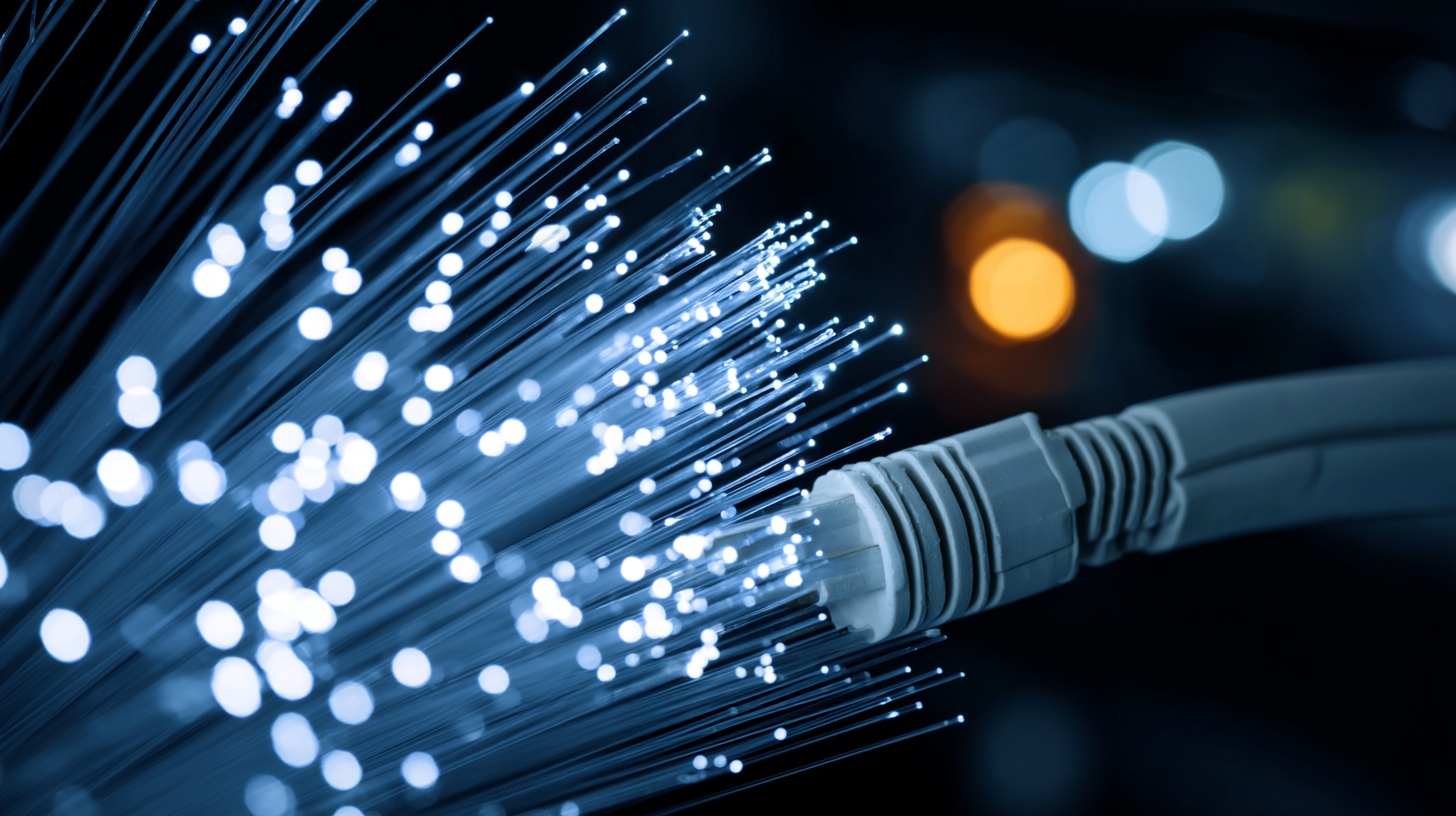

Plastic Optical Fiber (POF) extension cables are a critical component in modern optical communication systems. They offer a cost-effective and efficient solution for data transmission over short to medium distances. This article delves into the intricacies of POF extension cables, their applications, benefits, technical specifications, and considerations for implementation.

What is a Plastic Optical Fiber Extension Cable?

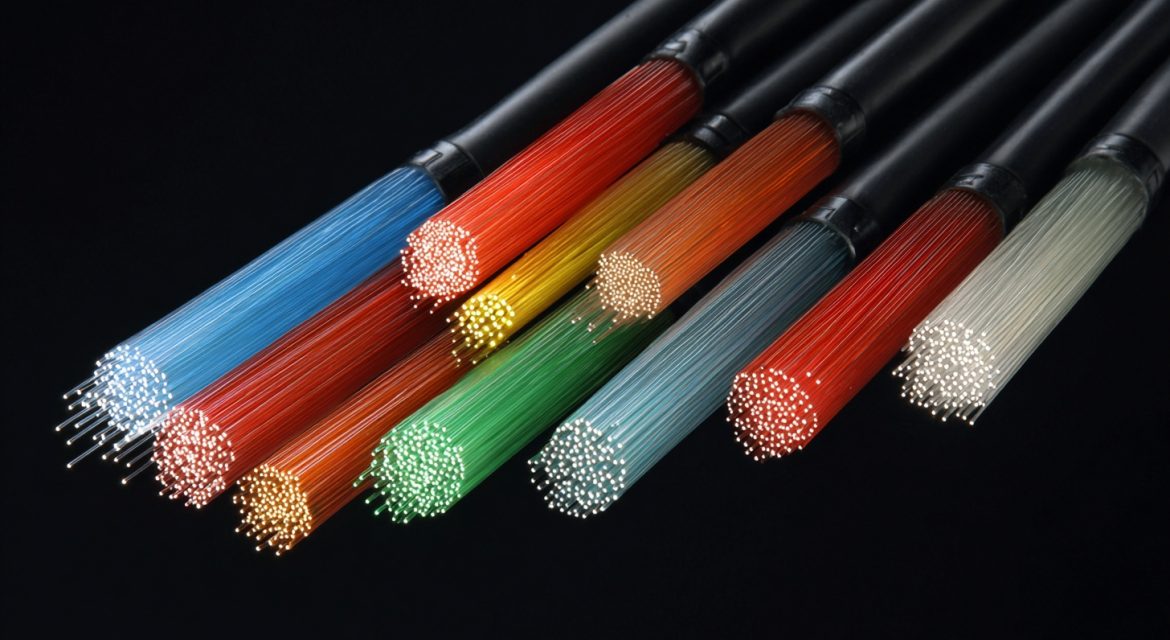

A plastic optical fiber extension cable is a type of fiber optic cable that uses plastic as the core material instead of glass. Unlike traditional glass-based optical fibers, which are used primarily in long-distance communication due to their high data transmission speeds and low signal loss, POF cables are designed for short-range applications where cost-effectiveness is a priority.

Key Features:

– Material: Typically made from polymethyl methacrylate (PMMA) or other plastic materials.

– Diameter: Usually thicker than glass fibers, which makes them easier to handle and splice.

– Transmission Range: Ideal for distances up to 10 kilometers, making them suitable for campus networks, industrial automation, and building management systems.

Technical Specifications

Understanding the technical specifications of a plastic optical fiber extension cable is essential for selecting the right product for your needs. Below are some key parameters to consider:

Core Diameter

The core diameter of POF cables ranges from 50 microns to several millimeters, depending on the application. A thicker core allows for higher light transmission but may result in increased signal loss over longer distances.

Cladding Thickness

The cladding thickness is typically around 75-125 microns and plays a crucial role in maintaining the integrity of the optical signal by reflecting light back into the core.

Attenuation

Attenuation, or signal loss, is measured in decibels per kilometer (dB/km). POF cables generally have higher attenuation compared to glass fibers, typically ranging between 10 dB/km and 25 dB/km. This makes them suitable for short-range applications where signal strength remains manageable.

Bandwidth

The bandwidth of a POF cable is lower than that of glass fiber, usually up to several hundred MHz·km. While this limits the maximum data transmission rate, it’s still sufficient for many industrial and commercial applications.

Applications of Plastic Optical Fiber Extension Cables

POF extension cables find application in various fields due to their unique advantages. Some common uses include:

– Industrial Automation: Connecting sensors, controllers, and other devices within a factory setting.

– Building Management Systems: Integrating security systems, lighting controls, and HVAC systems within a building.

– Telecom Infrastructure: Extending fiber optic networks in urban areas where cost and ease of installation are critical factors.

– Medical Equipment: Transmitting data between medical devices in hospitals or clinics.

Advantages of Plastic Optical Fiber Extension Cables

1. Cost-Effective: POF cables are significantly cheaper to produce than glass fibers, making them an economical choice for short-range applications.

2. Ease of Installation: The thicker core and cladding make POF cables easier to handle and splice, reducing installation time and complexity.

3. Flexibility: These cables are more flexible compared to glass fibers, allowing for easier routing in complex environments.

4. Resistance to EMI: Plastic optical fibers are immune to electromagnetic interference, ensuring reliable data transmission in electrically noisy environments.

5. Durability: POF cables are less susceptible to damage from environmental factors such as temperature fluctuations and moisture compared to traditional glass fibers.

Challenges and Limitations

Despite their advantages, plastic optical fiber extension cables do have some limitations:

1. Higher Attenuation: Higher signal loss over longer distances limits their effective range.

2. Lower Bandwidth: Compared to glass fibers, POF cables offer lower bandwidth, restricting data transmission rates.

3. Limited Applications: Best suited for short-range applications; not ideal for long-distance communication networks.

Choosing the Right Plastic Optical Fiber Extension Cable

Selecting the appropriate POF extension cable involves evaluating several factors:

– Distance Requirements: Determine the maximum distance over which the cable will be used to ensure adequate signal strength.

– Data Transmission Rate: Assess the necessary bandwidth for your application to choose a cable that meets your needs.

– Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to mechanical stress.

– Budget Constraints: Weigh the cost against performance requirements to find an optimal solution.

Conclusion

Plastic optical fiber extension cables provide a practical and cost-effective solution for short-range data transmission in various industries. By understanding their technical specifications, applications, and limitations, you can make informed decisions when integrating POF cables into your network infrastructure. Whether for industrial automation, building management, or telecom solutions, POF extension cables offer reliable performance and flexibility, making them a valuable component in modern optical communication systems.