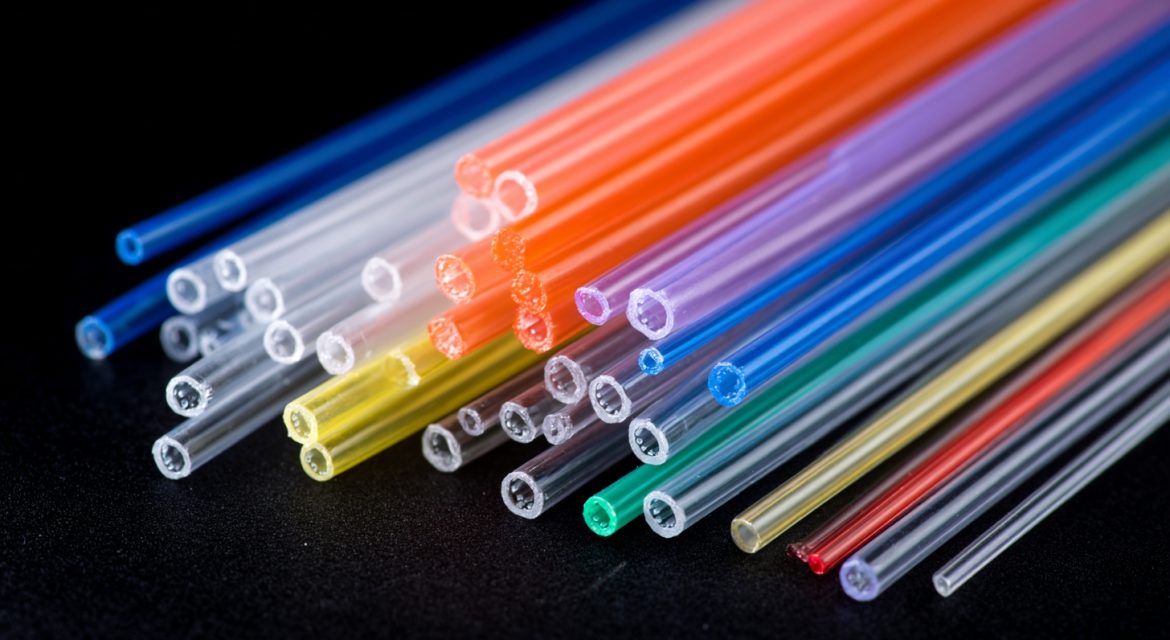

Understanding Plastic Optical Fiber Protection Sleeves

Plastic optical fibers (POFs) have become a cornerstone in modern telecommunications and data transmission systems. These versatile fibers are widely used due to their cost-effectiveness, ease of handling, and ability to transmit high-quality signals over short distances. However, like all optical fibers, POFs require proper protection to ensure optimal performance and longevity. This is where plastic optical fiber protection sleeves come into play.

What Are Plastic Optical Fiber Protection Sleeves?

Plastic optical fiber protection sleeves are protective coverings designed to safeguard POFs from environmental factors such as moisture, dust, mechanical stress, and temperature fluctuations. These sleeves not only enhance the durability of the fibers but also contribute to maintaining signal integrity during data transmission.

Key Features of Plastic Optical Fiber Protection Sleeves

1. Material Composition: Most protection sleeves are made from high-quality polymers or thermoplastics like PVC (polyvinyl chloride) or PE (polyethylene). These materials offer excellent resistance to environmental stressors and provide a smooth, flexible covering that protects the fiber without adding unnecessary bulk.

2. Durability: The sleeves must withstand harsh conditions, including extreme temperatures, UV radiation, and moisture exposure, ensuring long-term protection for the POFs.

3. Flexibility: A good protection sleeve should be flexible enough to allow easy installation and routing of the fibers through various pathways without causing damage to the fiber core.

4. Compatibility: The sleeves must be compatible with the specific type of POF being used, ensuring a snug fit that prevents microbending or macrobending issues which can degrade signal quality.

5. Sealing Mechanism: Some advanced sleeves come with sealing mechanisms to prevent moisture ingress, which is crucial in outdoor applications where humidity and water exposure are common.

Technical Parameters of Plastic Optical Fiber Protection Sleeves

When selecting a protection sleeve, it’s essential to consider several technical parameters:

– Outer Diameter (OD): The outer diameter should match the fiber management system or connector being used. Common sizes range from 2mm to 5mm depending on the application.

– Inner Diameter (ID): Must fit snugly around the POF without causing stress. Typical IDs are between 1.5mm and 3mm.

– Tensile Strength: Measures the sleeve’s ability to withstand pulling forces, usually expressed in Newtons per unit area.

– Flexibility at Low Temperatures: Important for applications in cold environments; measured by low-temperature flexibility tests.

– UV Resistance: Indicates how well the sleeve can resist degradation from prolonged UV exposure, often tested using accelerated weathering methods.

Applications of Plastic Optical Fiber Protection Sleeves

Plastic optical fiber protection sleeves find application in a variety of settings:

1. Telecommunications: Used to protect POFs in local area networks (LANs), fiber-to-the-home (FTTH) installations, and other telecom infrastructure.

2. Industrial Automation: Protecting fibers in industrial environments where exposure to chemicals, heat, and mechanical stress is common.

3. Medical Equipment: In medical devices where reliable data transmission is critical, sleeves ensure the integrity of optical signals.

4. Aerospace and Defense: Providing protection in high-performance environments with extreme temperature fluctuations and vibration.

5. Consumer Electronics: Used in devices like home theater systems, gaming consoles, and other consumer-grade electronics that utilize POFs for data transmission.

Installation and Maintenance Tips

1. Proper Fit: Ensure the sleeve fits snugly around the POF to prevent any movement or stress that could lead to signal degradation.

2. Clean Environment: Keep the installation area clean to avoid dust or debris getting inside the sleeve, which can cause microbending issues.

3. Avoid Over-Tensioning: Do not pull the fiber too tightly through the sleeve, as this can damage both the sleeve and the fiber.

4. Regular Inspections: Periodically check for any signs of wear, cracks, or moisture ingress in the sleeves to maintain optimal performance.

5. Use Quality Connectors: Pair the protection sleeves with high-quality connectors to ensure seamless signal transmission without loss or interference.

Conclusion

Plastic optical fiber protection sleeves are indispensable components in modern optical communication systems. By providing robust protection against environmental factors and mechanical stress, these sleeves ensure the longevity and reliability of POFs across various applications. Understanding their features, technical specifications, and proper installation techniques is crucial for maximizing their effectiveness and ensuring uninterrupted data transmission.

For more insights into optical fiber technologies and best practices, explore additional resources from industry experts and manufacturers.