Introduction

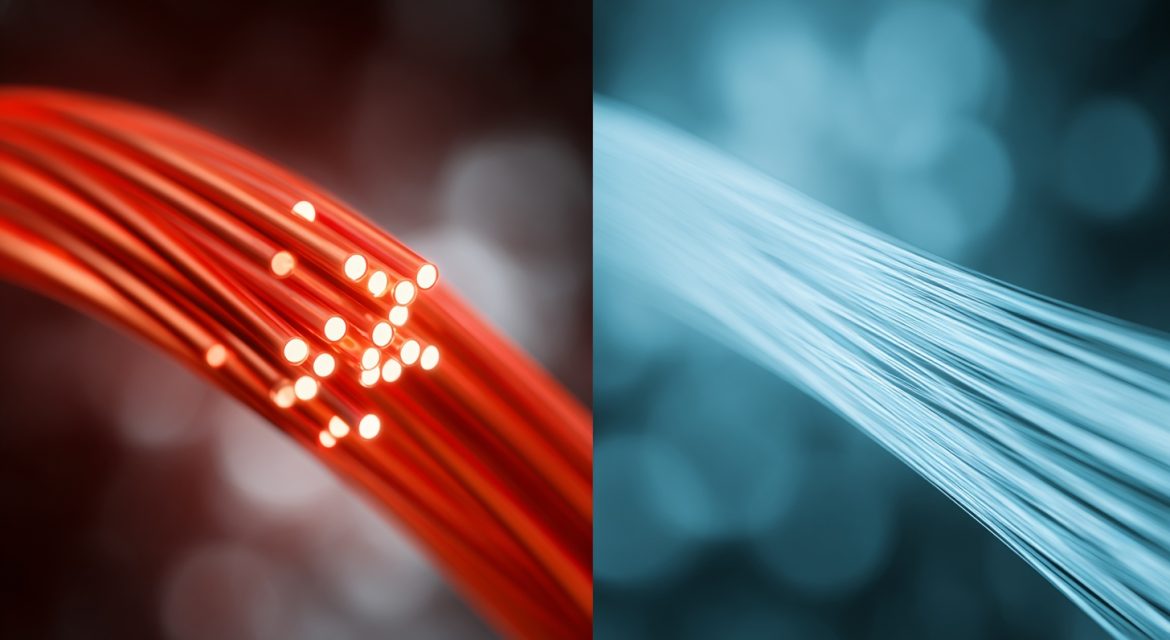

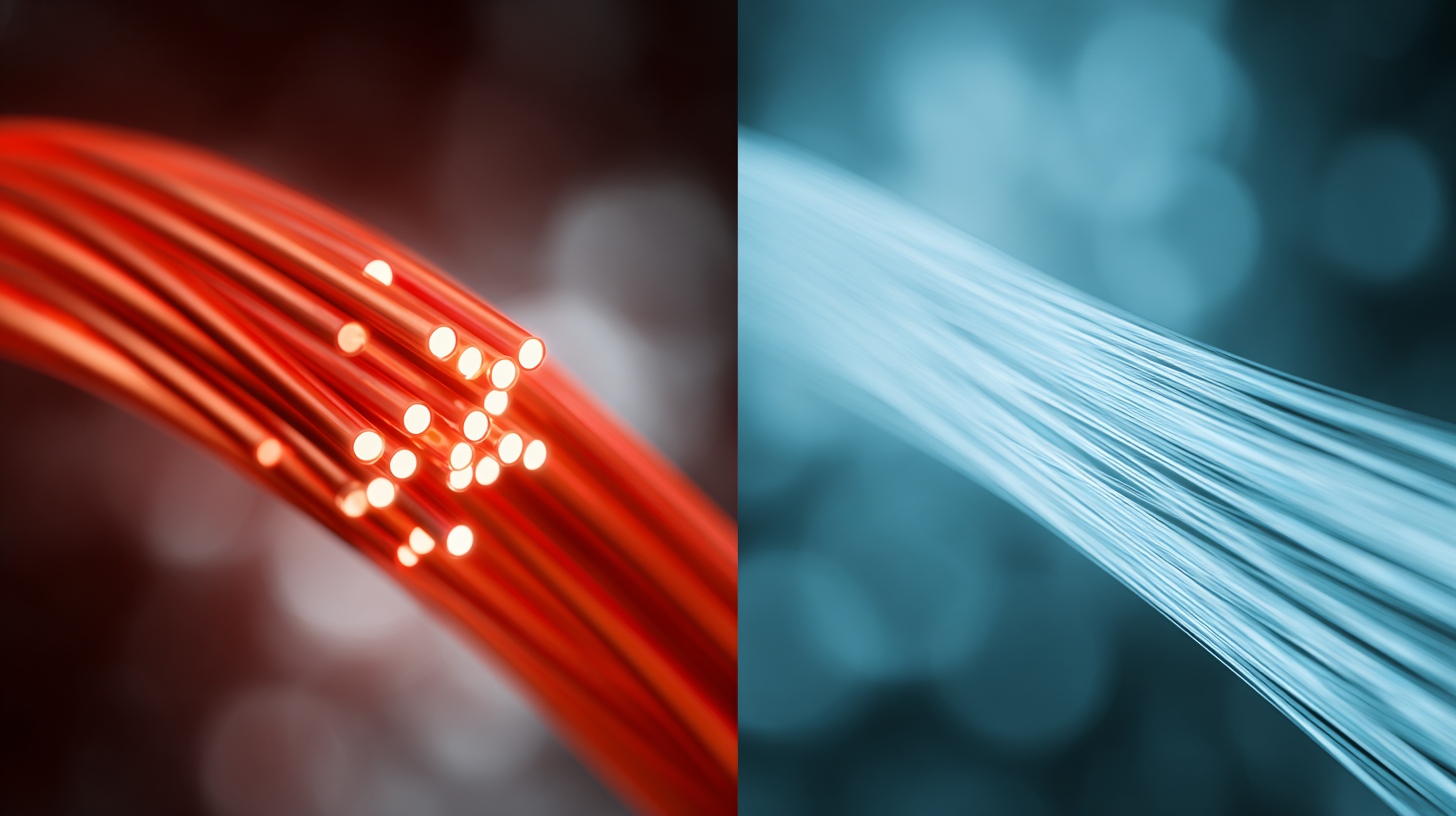

In the grand narrative of global telecommunications, Glass Optical Fiber (GOF) often steals the spotlight. It connects continents and powers the backbone of the internet. However, as we zoom in from the ocean floor to the dashboard of a car, the factory floor, or the living room wall, the narrative shifts.

While glass reigns supreme over long distances, Plastic Optical Fiber (POF) is emerging as the superior contender for “last-mile” and short-range data transmission. This article dissects the Plastic Optical Fiber vs. Glass Optical Fiber debate, revealing why POF’s unique material properties make it the more robust, cost-effective, and user-friendly choice for modern applications.

The Core Difference: Material and Mechanics

At a fundamental level, the distinction lies in the core. GOF utilizes a microscopic core of silica glass (often 9–62.5 microns), which is fragile and requires precision alignment.

POF, conversely, uses a general-purpose resin like PMMA (Polymethyl Methacrylate) with a significantly larger core diameter (typically 1mm or 1000 microns). This massive difference in size is not a drawback; it is POF’s greatest tactical advantage.

Why POF Wins in Short-Range Applications

While Glass Optical Fiber offers lower attenuation (signal loss) over kilometers, Plastic Optical Fiber dominates in environments where durability and ease of handling are paramount.

1. The “Do-It-Yourself” Installation Revolution

The most significant barrier to fiber adoption is the complexity of termination.

- GOF: Requires expensive fusion splicers, specialized polishing equipment, and highly trained technicians. A speck of dust can ruin a connection.

- POF: Can often be cut with a simple blade and connected without polishing. This “cut-and-plug” capability drastically reduces installation time and labor costs, making it ideal for home networking (FTTR) and automotive assembly lines.

2. Unmatched Durability and Flexibility

Glass breaks; plastic bends. In dynamic environments where cables are subject to vibration, bending, or physical stress—such as inside a robotic arm or a vehicle chassis—GOF is prone to micro-cracks and failure.

- Bend Radius: POF can withstand a much tighter bend radius (20mm or less) without significant signal loss or physical damage.

- Vibration Resistance: The polymer core is inherently more resilient to shock, making POF the standard in the automotive industry (MOST protocol) and industrial automation.

3. Total Cost of Ownership (TCO)

While raw glass cable can be cheap, the system cost tells a different story. POF utilizes visible red LED transceivers (650nm), which are significantly cheaper, more durable, and safer to the eye than the infrared laser diodes required for GOF. When you combine cheaper transceivers with lower installation labor costs, POF offers a far superior ROI for links under 100 meters.

Comparison at a Glance

| Feature | Plastic Optical Fiber (POF) | Glass Optical Fiber (GOF) |

| Core Material | PMMA / Polymer | Silica Glass |

| Core Diameter | ~1000 µm (Huge Sweet Spot) | 9 µm (SM) / 50-62.5 µm (MM) |

| Light Source | Red LED (Low Cost) | Laser / VCSEL (High Cost) |

| Installation | Simple “Cut & Plug” | Fusion Splicing / Polishing |

| Durability | High (Bend/Vibration Resistant) | Low (Fragile) |

| Best Use Case | Home, Auto, Industry (<100m) | Telecom Backbone, Long Haul |

The Verdict: The Right Tool for the Edge

The debate of Plastic Optical Fiber vs. Glass Optical Fiber is not about one replacing the other universally. It is about selecting the right tool for the job.

For trans-oceanic data, stick with glass. But for the smart home, the connected car, and the automated factory, Plastic Optical Fiber offers a blend of ruggedness, simplicity, and bandwidth (up to 1Gbps with SI-POF and higher with GI-POF) that glass simply cannot match. As we move toward a more connected edge, POF is ready to light the way.

You can take a look at our products