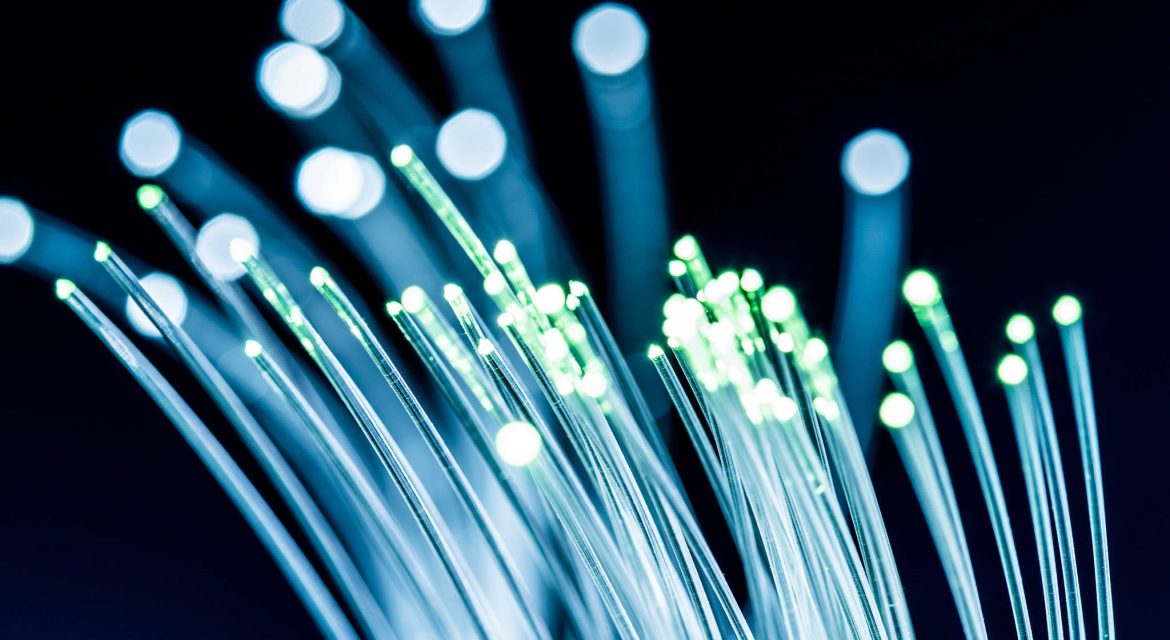

Understanding 0.5mm Plastic Optical Fiber: Applications and Benefits

Plastic Optical Fiber (POF) has become a popular choice for various optical communication applications due to its unique properties and advantages over traditional glass-based fibers. Among the different types of POF available, the 0.5mm plastic optical fiber stands out for its compact size, flexibility, and cost-effectiveness. This article delves into the technical aspects, applications, and benefits of using 0.5mm POF in various industries.

What is 0.5mm Plastic Optical Fiber?

Plastic Optical Fiber (POF) refers to optical fibers made from plastic materials, specifically polymethyl methacrylate (PMMA), which allows for efficient light transmission over short distances. The 0.5mm designation refers to the outer diameter of the fiber, making it one of the smallest available POF options. Despite its small size, this fiber offers excellent performance for specific applications.

Technical Specifications of 0.5mm POF

The technical characteristics of 0.5mm plastic optical fiber make it suitable for a variety of uses:

1. Core Diameter: Typically ranges from 90μm to 100μm, ensuring efficient light propagation.

2. Cladding Diameter: Usually around 500μm (0.5mm), providing robust protection and flexibility.

3. Numerical Aperture (NA): Generally higher than glass fibers, allowing for easier coupling of light sources.

4. Attenuation: Lower attenuation compared to other plastic fibers, enabling longer transmission distances within its optimal range.

5. Temperature Range: Can operate effectively in a wide temperature range, from -20°C to 80°C, making it suitable for diverse environments.

6. Flexibility: High flexibility due to the plastic material, allowing for easy installation and bending without signal degradation.

runfunc: 0; algolist: 0;

multi-frame: 1;

brp_mask:0;

brp_del_th:0.0000,0.0000;

brp_del_sen:0.0000,0.0000;

motionR: 0;

delta:null;

module: photo;hw-remosaic: false;touch: (-1.0, -1.0);sceneMode: 13107200;cct_value: 0;AI_Scene: (-1, -1);aec_lux: 331.0;aec_lux_index: 0;albedo: ;confidence: ;motionLevel: -1;weatherinfo: weather??, icon:2, weatherInfo:103;temperature: 30;

Advantages of Using 0.5mm Plastic Optical Fiber

Cost-Effective Solution

One of the primary advantages of 0.5mm POF is its lower cost compared to glass fibers. This makes it an ideal choice for applications where budget constraints are a concern, such as in consumer electronics and automotive industries.

Easy Installation

The flexibility and small diameter of this fiber make installation straightforward, even in confined spaces or challenging environments. It does not require specialized equipment or highly skilled personnel for deployment.

High Flexibility

The plastic material used in 0.5mm POF allows it to bend without causing signal loss, which is a common issue with glass fibers. This flexibility enhances its suitability for applications requiring frequent reconfiguration or movement of cables.

Reduced Signal Loss

Despite being made of plastic, the 0.5mm fiber exhibits lower attenuation compared to other types of plastic optical fibers, ensuring clearer and more reliable data transmission over longer distances within its design limits.

Wide Temperature Range

The ability to operate in a broad temperature range enhances its versatility for use in both indoor and outdoor environments, including industrial settings where temperature fluctuations are common.

Applications of 0.5mm Plastic Optical Fiber

The unique features of 0.5mm POF make it suitable for a wide array of applications across different industries:

1. Automotive Industry: Used in vehicle communication systems, such as CAN bus networks and interior lighting controls.

2. Consumer Electronics: Ideal for short-distance data transmission in devices like TVs, audio equipment, and home automation systems.

3. Industrial Automation: Employed in factory automation for control signals and sensor data transmission.

4. Medical Equipment: Used in medical devices where lightweight, flexible, and durable fibers are required for diagnostic and monitoring purposes.

5. Avionics: Applied in aircraft communication and control systems due to its lightweight and flexibility.

6. Building Automation: Utilized in smart building systems for data transmission between sensors, actuators, and control units.

Challenges and Limitations

While 0.5mm POF offers numerous advantages, it also has some limitations that need to be considered:

1. Limited Bandwidth: Compared to glass fibers, plastic optical fibers have lower bandwidth capabilities, which restricts their use in high-speed data transmission applications.

2. Distance Limitations: Although attenuation is relatively low for plastic fibers, the maximum distance for effective communication is shorter than that of glass fibers, typically up to a few hundred meters.

3. Signal Quality: The higher numerical aperture can lead to increased modal dispersion, which may affect signal quality over longer distances or in high-frequency applications.

Conclusion

The 0.5mm plastic optical fiber represents an excellent balance between cost-effectiveness, flexibility, and performance for a variety of short-distance communication needs. Its wide range of applications across industries underscores its versatility as a reliable solution for modern optical communication systems. By understanding its technical specifications and limitations, engineers and designers can make informed decisions about whether 0.5mm POF is the right choice for their specific requirements.

References

– [Plastic Optical Fiber Basics](https://www.example.com/pof-basics)

– [Technical Specifications of POF](https://www.example.com/pof-specs)

– [Applications of Plastic Optical Fibers](https://www.example.com/pof-applications)