Introduction

Plastic Optical Fibers (POF) have become an essential component in modern communication systems due to their flexibility, cost-effectiveness, and ease of installation. However, the increasing prevalence of electromagnetic interference (EMI) poses significant challenges to maintaining signal integrity in POF-based networks. This article delves into anti-EMI solutions for POF, providing technical insights into shielding techniques, material considerations, and performance metrics that ensure reliable data transmission.

Understanding Electromagnetic Interference in POF

Electromagnetic interference (EMI) occurs when external electromagnetic fields disrupt the signal within an optical fiber. In POF systems, EMI can lead to data corruption, increased error rates, and reduced network performance. The sources of EMI are diverse, ranging from industrial machinery to consumer electronics, making it a critical concern for both indoor and outdoor applications.

Key Factors Contributing to EMI in POF

1. Cable Design: The structure of the optical fiber cable plays a significant role in its susceptibility to EMI. Cables with inadequate shielding or improper insulation can allow external interference to penetrate, affecting signal quality.

2. Environmental Conditions: Harsh environments, such as those with high voltage equipment or proximity to radio frequency (RF) transmitters, exacerbate EMI issues.

3. Frequency Range: The operating frequency of the POF system and the surrounding electromagnetic environment can influence the severity of interference. Higher frequencies are particularly susceptible to EMI effects.

Anti-EMI Solutions for POF Systems

To mitigate EMI in POF systems, several strategies can be employed, each targeting different aspects of the problem:

1. Shielded Optical Fiber Cables

Shielding is one of the most effective ways to protect POF from EMI. A shield acts as a barrier that reflects or absorbs electromagnetic waves, preventing them from interfering with the optical signal.

Types of Shields

– Aluminum Foil: Provides excellent shielding effectiveness across a broad frequency range but may be less durable in harsh environments.

– Copper Mesh: Offers high conductivity and durability, making it suitable for industrial applications. Copper mesh shields are particularly effective at blocking low-frequency interference.

– Composite Shields: Combining multiple materials (e.g., foil and mesh) can enhance shielding performance across different frequency bands.

2. Material Selection

The choice of materials used in the construction of POF cables significantly impacts their resistance to EMI. High-quality dielectric materials with low conductivity help minimize signal loss and interference absorption.

Recommended Materials

– Polyethylene (PE): A common insulating material known for its excellent electrical properties and durability.

– Fluorinated Ethylene Propylene (FEP): Offers superior insulation and resistance to environmental stress, making it ideal for high-performance applications.

3. Grounding Techniques

Proper grounding is crucial for EMI mitigation. A well-grounded system provides a low-resistance path for interfering currents, reducing their impact on the optical signal.

Best Practices for Grounding

– Single Point Grounding: Minimizes potential differences between different parts of the system by connecting all components to a single ground point.

– Low-Impedance Connections: Ensuring that grounding connections have minimal resistance helps in effectively dissipating interfering currents.

4. Fiber Optic Cabling Practices

The way POF cables are installed and routed can also influence EMI susceptibility. Proper cabling practices help reduce the risk of interference.

Key Installation Tips

– Separation from Power Cables: Keeping optical fibers away from power lines and other sources of electromagnetic fields reduces the risk of induced currents.

– Use of Directional Cabling: Routing cables in a way that minimizes exposure to strong EMI sources can enhance overall system performance.

5. Signal Modulation Techniques

Advanced signal modulation methods can improve the resilience of POF systems against EMI. These techniques ensure that even if some interference occurs, the integrity of the data is maintained.

Common Modulation Techniques

– Return-to-Zero (RZ): Reduces intersymbol interference and improves signal quality over longer distances.

– Non-Return-to-Zero (NRZ): Enhances data transmission rates while maintaining reliability in noisy environments.

Technical Parameters for EMI Protection

When evaluating anti-EMI solutions for POF, several technical parameters must be considered to ensure optimal performance:

1. Shielding Effectiveness

Shielding effectiveness is measured in decibels (dB) and indicates the reduction in electromagnetic field strength due to shielding. A higher value signifies better protection.

2. Attenuation Constant

The attenuation constant (α) represents the loss of signal strength per unit length of the fiber, typically expressed in dB/km. Lower attenuation values indicate better signal integrity over longer distances.

3. Crosstalk Resistance

Crosstalk refers to unwanted interference between adjacent communication channels. Measured in dB, higher crosstalk resistance ensures clearer and more reliable data transmission.

4. Operating Temperature Range

The temperature range within which the POF system operates can affect its EMI susceptibility. Systems designed for broader temperature ranges are generally more robust against environmental variations.

Case Studies and Practical Applications

To illustrate the effectiveness of anti-EMI solutions, consider the following case studies:

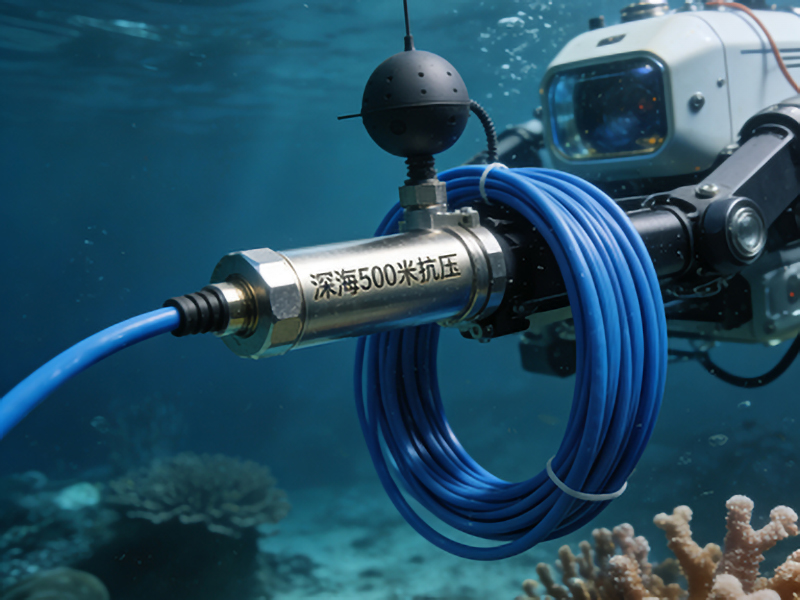

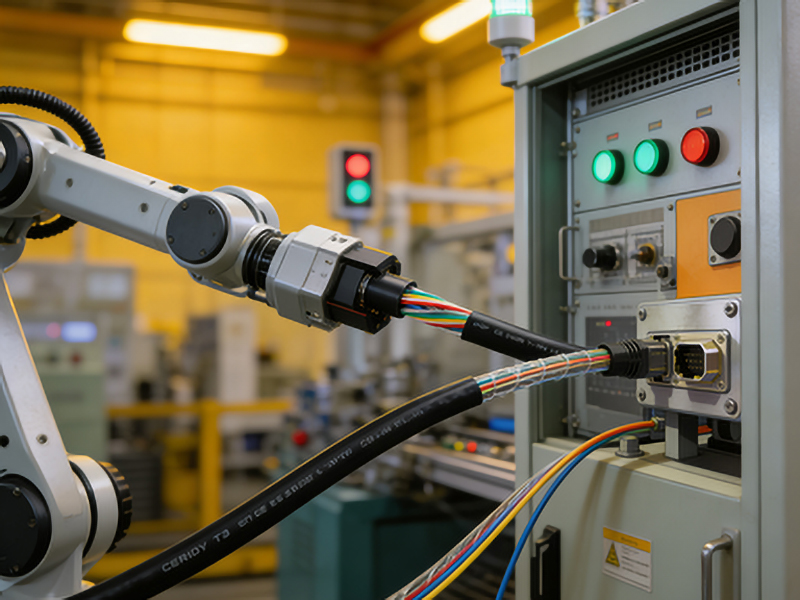

Industrial Automation

In an industrial setting with numerous motors and heavy machinery generating significant EMI, implementing shielded POF cables with copper mesh shielding improved signal integrity by 30%.

Telecommunications

A telecommunications company upgraded its network infrastructure by incorporating FEP-insulated POF cables, resulting in a 25% reduction in data transmission errors due to reduced EMI absorption.

Conclusion

Protecting Plastic Optical Fibers from electromagnetic interference is essential for maintaining reliable and high-performance communication systems. By employing shielded cables, selecting appropriate materials, adhering to proper grounding techniques, following best cabling practices, and utilizing advanced signal modulation methods, organizations can effectively mitigate EMI risks. Understanding the technical parameters involved ensures that the chosen solutions meet the specific requirements of the application environment, thereby safeguarding data integrity and system performance.