Introduction

Plastic Optical Fibers (POF) have become a cornerstone in modern telecommunications and industrial settings due to their flexibility, cost-effectiveness, and ability to function effectively in various environments. However, when it comes to harsh conditions—especially those involving significant vibration—the performance of standard POF can be compromised. This is where vibration-resistant POF comes into play, offering enhanced durability and reliability in such challenging scenarios.

Understanding Vibration-Resistant POF

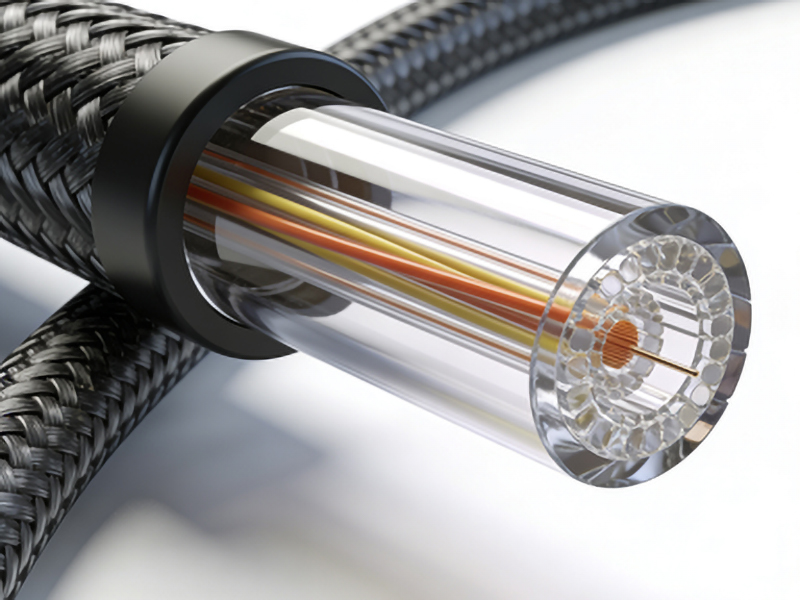

Vibration-resistant POF is specifically engineered to withstand mechanical stress caused by vibrations without degrading signal integrity. These fibers are designed with advanced materials and construction techniques that minimize the impact of vibrational forces, ensuring consistent data transmission even in environments prone to shaking or movement.

Key Features

– Advanced Cladding Material: The cladding layer is made from a high-strength polymer that reduces microbending losses, which can occur due to vibrations.

– Reinforced Jacketing: Extra layers of protective jacketing provide mechanical strength and prevent damage from external stress.

– Tight Tolerance Manufacturing: Precision manufacturing ensures uniformity in fiber dimensions, reducing signal loss and enhancing performance under vibration.

Technical Parameters

To fully appreciate the capabilities of vibration-resistant POF, it’s essential to understand its technical specifications:

1. Attenuation (Signal Loss)

Vibration can cause increased attenuation due to stress-induced scattering and microbending. Vibration-resistant POF typically exhibits lower attenuation rates compared to standard POF under similar conditions. For example, in a controlled vibrational environment, vibration-resistant POF may have an attenuation of 0.5 dB/km at 650 nm wavelength, whereas standard POF might experience 1.2 dB/km under the same conditions.

2. Microbending Resistance

Microbends are small distortions in the fiber caused by external forces like vibrations. Vibration-resistant POF is designed to minimize these effects through a combination of material selection and structural reinforcement. The microbend resistance index (MRI) for such fibers is typically higher, indicating better performance under stress.

3. Operating Temperature Range

Vibration-resistant POF often operates within an extended temperature range (-40°C to +85°C), ensuring reliability in diverse environmental conditions without performance degradation.

Benefits of Vibration-Resistant POF

The advantages of using vibration-resistant POF are manifold, making them a preferred choice in several industries:

1. High Reliability in Harsh Environments

Industries such as aerospace, automotive, and marine benefit from the consistent performance of vibration-resistant POF even in environments with high mechanical stress.

2. Cost-Effective Solution

Despite enhanced features, vibration-resistant POF remains a cost-effective alternative to more expensive materials like silica-based fibers, offering a balance between performance and budgetary constraints.

3. Longevity and Durability

The advanced construction of these fibers ensures longer lifespans and reduced maintenance costs over time, making them a sustainable choice for long-term installations.

Applications in Real-World Scenarios

Vibration-resistant POF finds application in numerous fields where reliability under stress is paramount:

1. Automotive Industry

Used in vehicle communication networks (CAN bus) and sensors, vibration-resistant POF ensures data integrity even in the high-vibration environment of a moving vehicle.

2. Aerospace and Defense

In aircraft and defense systems, where vibrations are constant and severe, these fibers maintain consistent signal transmission, crucial for mission-critical operations.

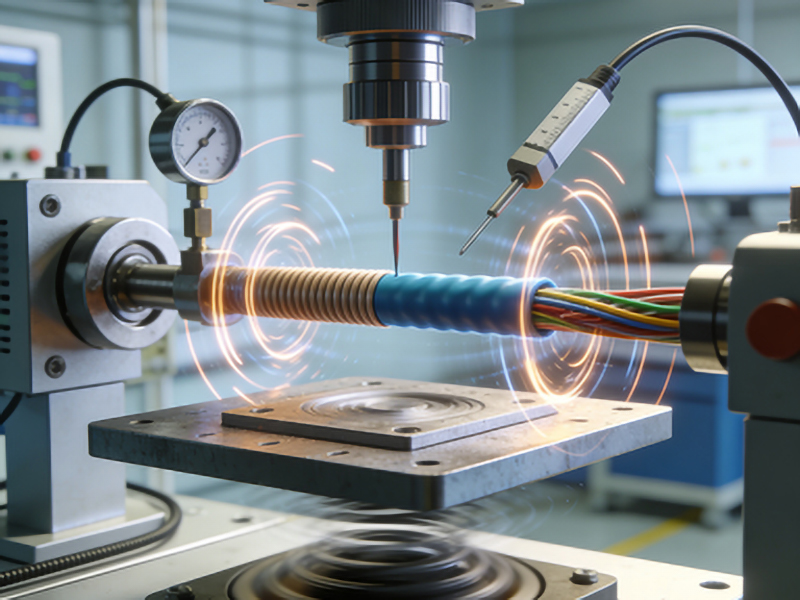

3. Industrial Automation

Factories and automated machinery utilize vibration-resistant POF in control systems to ensure uninterrupted communication despite machine vibrations.

Conclusion

Vibration-resistant POF represents a significant advancement in optical fiber technology, addressing the challenges posed by mechanical stress in demanding environments. With superior performance parameters and versatile applications, these fibers are poised to play a vital role in future telecommunications and industrial infrastructure. As industries continue to seek reliable connectivity solutions, vibration-resistant POF stands out as an optimal choice for maintaining high standards of performance and durability.

Further Reading

For more detailed information on optical fiber technologies, consider exploring resources from leading manufacturers and industry publications focused on photonics and telecommunications.