Introduction

Plastic Optical Fiber (POF), also known as polymer optical fiber, is a type of optical fiber primarily used for short-distance data transmission. Unlike traditional glass-based optical fibers, POF utilizes plastic materials for both the core and cladding, offering unique advantages in cost, flexibility, and ease of use. This article delves into the technical aspects, applications, and benefits of POF in various industries.

Technical Overview

Core and Cladding Materials

The core of a POF is typically made from polymethyl methacrylate (PMMA), while the cladding consists of fluorinated polymer or other materials with lower refractive indices. This construction allows for efficient light transmission within the fiber.

Bandwidth and Loss Characteristics

POF exhibits higher signal loss compared to glass fibers, making it suitable for shorter-distance applications. The bandwidth is generally lower, around 100 MHz·km to 500 MHz·km, which limits its use to environments where high-speed data transmission over long distances isn’t required.

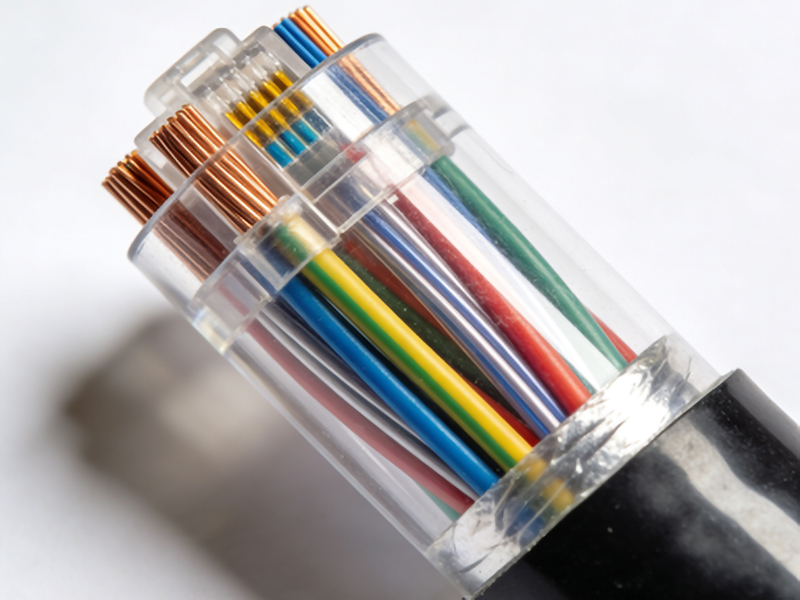

Connectorization

POF uses connectors similar to those used in glass fibers but with different termination methods due to the material differences. The most common connectors include FC, SC, and ST types, adapted for POF’s unique properties.

Applications of Plastic Optical Fiber

Lighting Systems

One of the earliest applications of POF is in lighting systems, such as architectural lighting and decorative installations. Its flexibility and brightness make it ideal for creative lighting solutions.

Data Communication

POF is widely used in local area networks (LANs), industrial automation, and automotive communication systems. Its low cost and ease of installation make it a popular choice for these applications.

Sensors

POF-based sensors are employed in various industries for measuring parameters like temperature, pressure, and strain. The fiber’s flexibility allows it to be embedded in structures for continuous monitoring.

Advantages of POF

1. Cost-Effective: POF is significantly cheaper than glass fibers due to the use of plastic materials and simpler manufacturing processes.

2. Flexible: The plastic material offers greater flexibility, making it easier to install in tight spaces or curved environments.

3. Ease of Use: POF requires less specialized tools for termination and splicing compared to glass fibers, reducing installation complexity.

4. Durable: Despite being made from plastic, POF is resistant to environmental factors like moisture and temperature variations, enhancing its longevity.

Challenges and Limitations

1. Signal Loss: Higher attenuation compared to glass fibers limits the distance over which signals can be transmitted effectively.

2. Bandwidth Limitations: The lower bandwidth makes it unsuitable for high-speed, long-distance applications typically handled by glass fibers.

3. Temperature Sensitivity: POF’s performance can degrade at extreme temperatures, affecting signal integrity.

Conclusion

Plastic Optical Fiber offers a cost-effective and flexible solution for short-distance communication and lighting applications. While it may not replace traditional glass-based fibers in all scenarios, its unique advantages make it an invaluable tool in specific industrial and commercial settings. As technology evolves, POF continues to find new applications, solidifying its role in the fiber optics landscape.