Introduction to PMMA Plastic Optical Fibers

Plastic Optical Fibers (POFs) have become an integral part of modern optical communication systems, offering a cost-effective and versatile solution for data transmission. Among the various types of POFs, Polymethyl Methacrylate (PMMA) stands out as one of the most widely used materials due to its excellent optical properties and manufacturing compatibility.

Optical Properties of PMMA

PMMA exhibits several key characteristics that make it suitable for optical fiber applications:

– High Clarity: PMMA has a high refractive index, enabling efficient light transmission over long distances with minimal loss.

– Transparency: It is highly transparent in the visible and near-infrared spectrum, making it ideal for various communication needs.

– Mechanical Strength: Compared to other plastics, PMMA offers better mechanical durability, reducing the risk of fiber breakage during installation or use.

Technical Parameters of PMMA Optical Fibers

Understanding the technical specifications is crucial for selecting the right PMMA optical fiber for your application:

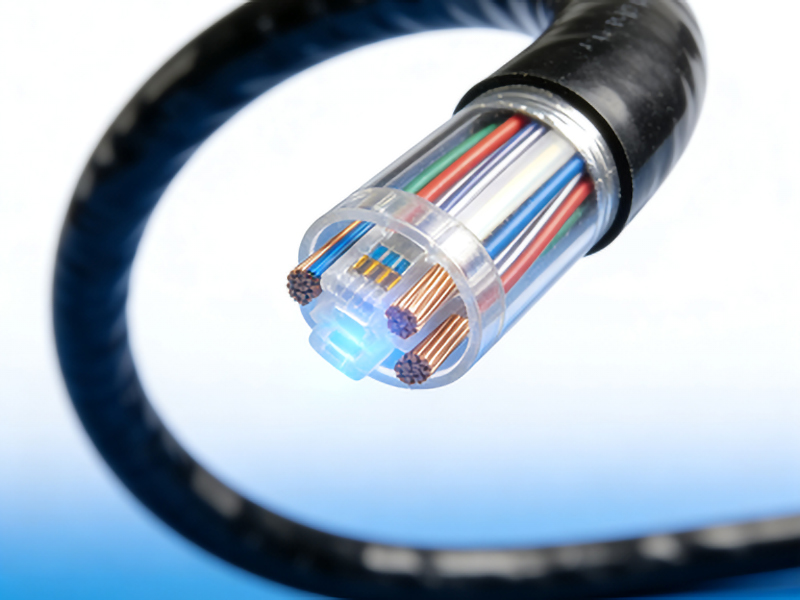

– Core Diameter: Typically ranges from 50 μm to 1 mm. Smaller diameters are preferred for higher data rates, while larger ones offer better light-gathering capability.

– Cladding Thickness: Usually between 25 μm and 500 μm. The cladding helps in total internal reflection, ensuring minimal signal loss.

– Attenuation Coefficient: PMMA fibers typically have an attenuation coefficient of around 1 dB/m at visible wavelengths, which is higher than glass fibers but acceptable for short-distance applications.

– Numerical Aperture (NA): Ranges from 0.4 to 0.55. A higher NA allows more light to enter the fiber, increasing its efficiency in capturing signals.

Applications of PMMA Optical Fibers

PMMA optical fibers find application across various industries due to their unique properties:

– Data Communication: Used in local area networks (LANs) for short-distance data transmission within buildings or campuses.

– Lighting Systems: Employed in decorative and architectural lighting solutions where flexible and lightweight fiber is required.

– Medical Devices: Utilized in endoscopes and other medical imaging equipment due to their flexibility and biocompatibility.

– Automotive Industry: Integrated into vehicle communication systems for data transmission between components like sensors and control units.

Advantages of PMMA Optical Fibers

1. Cost-Effective: PMMA is less expensive than glass, making POFs a budget-friendly option for many applications.

2. Flexibility: The plastic material allows the fibers to bend without breaking, offering design flexibility in complex systems.

3. Ease of Use: Simpler manufacturing processes and termination methods compared to glass fibers reduce installation complexity.

4. Lightweight: Lower weight makes them ideal for applications where space and weight are constraints.

Limitations of PMMA Optical Fibers

While PMMA optical fibers offer numerous benefits, they also have some limitations:

1. Higher Attenuation: Compared to glass fibers, PMMA has higher signal loss, limiting their use to short-distance applications.

2. Temperature Sensitivity: PMMA fibers can degrade under high temperatures or prolonged exposure to UV light, affecting performance over time.

3. Limited Bandwidth: Due to material dispersion, the bandwidth of PMMA fibers is lower than that of glass fibers, restricting data rates.

Conclusion

PMMA plastic optical fibers are a versatile and cost-effective solution for various applications in fields such as communications, lighting, medical devices, and automotive systems. While they have limitations in terms of signal loss and bandwidth, their flexibility and ease of use make them an attractive choice for short-distance communication needs. Understanding the technical parameters and application-specific requirements is essential to maximize their performance and reliability.