Introduction

Large-Diameter Plastic Optical Fiber (POF) has become a critical component in various communication and sensing systems due to its unique properties and advantages over traditional glass-based optical fibers. This article delves into the characteristics, applications, technical specifications, and future trends of large-diameter POF.

What is Large-Diameter Plastic Optical Fiber?

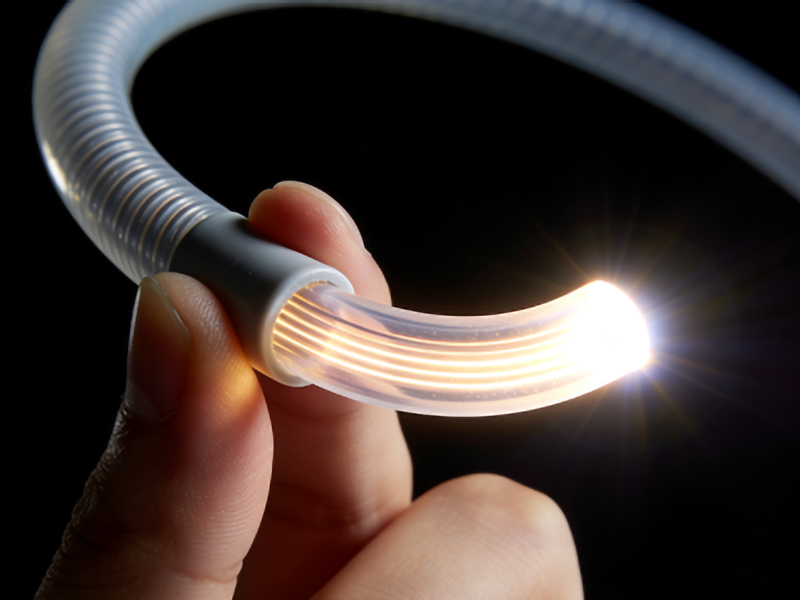

Plastic Optical Fiber (POF) refers to a type of optical fiber made from plastic materials, as opposed to the more common silica-based glass fibers. Large-diameter POF typically has a core diameter ranging from 500 micrometers (µm) up to several millimeters, significantly larger than standard single-mode or multi-mode glass fibers.

Key Features of Large-Diameter POF

1. High Light-Carrying Capacity: The large core size allows for higher light transmission compared to smaller diameter fibers, making them suitable for applications requiring high brightness and low loss.

2. Ease of Use: The larger diameter facilitates easier coupling of light sources, reducing alignment sensitivity and making integration into systems more straightforward.

3. Cost-Effective: Plastic materials are generally cheaper than silica glass, leading to lower production costs and overall system cost efficiency.

4. Flexibility: POF is highly flexible, enabling it to be used in environments where bending or twisting is common without significant signal degradation.

5. Durability: The plastic cladding provides excellent mechanical strength and resistance to environmental factors such as temperature fluctuations and humidity.

Technical Specifications

Understanding the technical parameters of large-diameter POF is essential for selecting the right fiber for specific applications. Key specifications include:

Core Diameter

– Range: 500 µm to several millimeters

– Impact on Performance: A larger core diameter allows for higher numerical aperture (NA), enabling better light collection and transmission efficiency.

Numerical Aperture (NA)

– Definition: NA is a measure of the fiber’s ability to collect incoming light. Higher NA means a wider acceptance angle, making coupling easier.

– Typical Values: For large-diameter POF, NA ranges from 0.2 to 0.5, depending on the specific application requirements.

Attenuation

– Definition: The reduction in signal strength as light travels through the fiber.

– Factors Influencing Attenuation: Material quality, impurities, and manufacturing defects can affect attenuation levels.

– Typical Values: Large-diameter POF typically has lower attenuation compared to smaller fibers due to their larger core size, but exact values vary by type and application.

Bandwidth

– Definition: The range of frequencies or wavelengths that the fiber can effectively transmit.

– Relevance for Applications: Higher bandwidth is crucial for applications requiring high data rates or simultaneous transmission of multiple signals.

Applications of Large-Diameter Plastic Optical Fiber

Large-diameter POF finds application in a wide array of fields due to its unique combination of properties. Some of the key areas include:

Lighting and Illumination

– High-Brightness Applications: Used in medical lighting, automotive headlamps, and decorative lighting where high brightness is essential.

– Advantages: The large core size allows for efficient light transmission with minimal loss, ensuring bright illumination over long distances.

Communication Systems

– Data Transmission: Employed in local area networks (LANs), industrial communication systems, and smart home automation.

– Benefits: Cost-effective, easy to install, and resistant to electromagnetic interference, making them ideal for environments with high EMI risks.

Sensing Applications

– Optical Sensors: Used in temperature, pressure, and strain sensors where the fiber’s flexibility and sensitivity are advantageous.

– Industrial Monitoring: Applied in monitoring systems within industrial settings for process control and safety.

Medical Imaging

– Endoscopy: Large-diameter POF is used in medical endoscopes to provide high-quality imaging with minimal invasiveness.

– Advantages: Flexible, biocompatible materials make them suitable for use in delicate medical procedures.

Advantages and Limitations

Advantages

1. Cost Efficiency: Lower production costs compared to glass fibers.

2. Ease of Handling: Easier to splice and connect due to their larger diameter.

3. Flexibility: Higher flexibility reduces the risk of breakage during installation or use in dynamic environments.

4. Signal Quality: While attenuation is higher than in some glass fibers, large-diameter POF compensates with a wider NA for better light capture and transmission efficiency.

Limitations

1. Higher Attenuation: Compared to certain types of glass fibers, POF may have higher signal loss over long distances.

2. Limited Bandwidth: The larger core size can limit the bandwidth compared to smaller diameter fibers optimized for high-speed data transmission.

3. Temperature Sensitivity: Some plastic materials are sensitive to temperature changes, potentially affecting performance in extreme conditions.

4. Durability Concerns: While generally durable, certain plastics may degrade over time with exposure to UV light or harsh chemicals.

Future Trends and Innovations

The field of optical fibers is continuously evolving, and large-diameter POF is no exception. Key trends include:

Enhanced Material Science

– Development of New Plastics: Research into new plastic materials that offer improved mechanical properties, thermal stability, and reduced attenuation.

– Nanotechnology Integration: Incorporating nanomaterials to enhance the optical properties of POF, such as increased transparency or better light-guiding capabilities.

Miniaturization and Customization

– Custom Fiber Design: Tailoring fiber dimensions and properties for specific applications, balancing between core size, NA, and attenuation for optimal performance.

– Integration with Other Technologies: Combining POF with other technologies like LEDs and photodetectors to create more efficient optical systems.

Increased Adoption in Smart Systems

– Internet of Things (IoT): As IoT devices proliferate, large-diameter POF is expected to play a significant role in providing reliable, low-cost connectivity solutions.

– Automotive Applications: Growing use in vehicle communication networks and lighting systems due to their resistance to EMI and flexibility.

Conclusion

Large-Diameter Plastic Optical Fiber offers a unique set of advantages that make it an invaluable component in various applications across industries. While they have certain limitations compared to glass fibers, ongoing advancements in materials science and manufacturing techniques are continually improving their performance and expanding their potential uses. As technology progresses, large-diameter POF is poised to play an even more critical role in the development of future optical systems.