Introduction

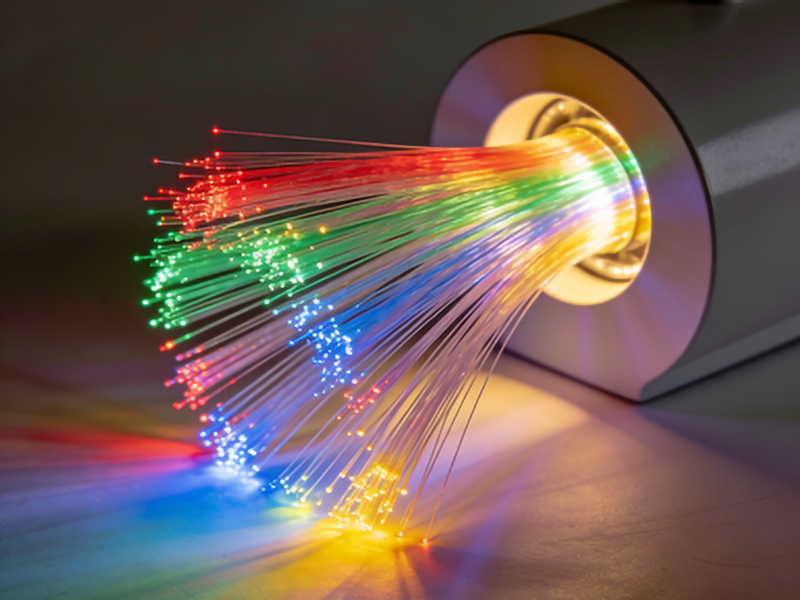

Plastic Optical Fiber (POF), also known as polymer optical fiber, has emerged as a versatile material in the field of lighting technology. This article delves into the applications and advantages of POF in lighting solutions, providing insights into its technical aspects and real-world implementations.

What is Plastic Optical Fiber?

Plastic Optical Fiber (POF) is a type of optical fiber made from plastic materials, primarily polymethyl methacrylate (PMMA). Unlike traditional glass optical fibers used in telecommunications, POF is designed for applications where flexibility, ease of use, and cost-effectiveness are prioritized.

Key Features of Plastic Optical Fiber

– High Flexibility: POF is highly flexible, making it suitable for applications that require bending or shaping without compromising performance.

– Cost-Effective: The production process for POF is less complex than glass fibers, leading to lower costs and wider accessibility.

– Ease of Handling: POFs are easier to install and handle due to their material properties and compatibility with standard connectors.

Technical Specifications of Plastic Optical Fiber

Understanding the technical parameters of POF is essential for selecting the right solution for lighting applications. Below are some key specifications:

Core Diameter

The core diameter of POF typically ranges from 0.5mm to several millimeters, depending on the application requirements. A larger core allows for higher light transmission but may reduce resolution in certain contexts.

Numerical Aperture (NA)

The numerical aperture is a measure of the fiber’s ability to capture and transmit light. For POF, NA values generally range from 0.4 to 0.5, indicating efficient light collection compared to glass fibers with lower NAs.

Attenuation

Attenuation in POF is higher than in glass fibers, typically ranging between 10 dB/km and 20 dB/km at visible wavelengths. This makes POF less suitable for long-distance communication but ideal for short-range lighting applications.

Temperature Range

POF can operate within a temperature range of -40°C to +80°C, making it suitable for both indoor and outdoor lighting environments.

Applications of Plastic Optical Fiber in Lighting

Plastic Optical Fiber is finding extensive use across various lighting applications due to its unique properties. Below are some key areas where POF is making an impact:

Architectural Lighting

Architects and designers utilize POF for creating dynamic, energy-efficient lighting solutions in buildings. The flexibility of POF allows for intricate designs, such as illuminated walls or ceilings, while maintaining low power consumption.

Automotive Lighting

In the automotive industry, POF is used for interior lighting applications such as dashboard illumination, ambient lighting, and decorative elements. The lightweight nature of POF contributes to reduced vehicle weight, enhancing fuel efficiency.

Consumer Electronics

Consumer electronics, including LED strips and smart home lighting systems, often incorporate POF for its flexibility and ability to transmit bright, colorful light efficiently.

Medical Lighting

In medical settings, POF is employed for surgical lighting and endoscopic applications. Its high flexibility and resistance to chemical agents make it ideal for these environments.

Advantages of Using Plastic Optical Fiber in Lighting

The adoption of POF in lighting solutions offers several advantages over traditional methods:

Energy Efficiency

POF allows for precise control of light distribution, minimizing energy loss and reducing overall power consumption.

Design Flexibility

With its high flexibility, POF enables innovative designs that were previously unattainable with rigid materials, leading to unique lighting solutions.

Cost-Effectiveness

The lower production costs associated with POF result in more affordable lighting systems without compromising quality or performance.

Safety and Reliability

POF is non-conductive and resistant to electromagnetic interference, ensuring safe operation in a variety of environments. Additionally, its durability reduces the likelihood of failures over time.

Challenges and Considerations

While Plastic Optical Fiber offers numerous benefits, there are some challenges to consider:

Limited Distance for Light Transmission

Due to higher attenuation compared to glass fibers, POF is best suited for short-distance applications where light needs to travel a limited distance.

Material Degradation Over Time

POF can degrade over time when exposed to UV light or harsh environmental conditions. Proper installation and protective measures are essential to ensure longevity.

Conclusion

Plastic Optical Fiber is revolutionizing the lighting industry with its unique combination of flexibility, cost-effectiveness, and energy efficiency. As technology continues to advance, POF is expected to find even more applications in both traditional and emerging fields. By understanding the technical aspects and application possibilities, professionals can harness the full potential of POF in creating innovative lighting solutions.