Introduction

Optical fibers have revolutionized the way we transmit data, providing high-speed, reliable communication across vast distances. Among the many types of optical fibers available, Anti-Interference Plastic Optical Fiber (POF) stands out for its unique properties and advantages in specific applications. This article delves into the world of anti-interference POF, exploring its features, benefits, technical specifications, and real-world applications.

What is Anti-Interference Plastic Optical Fiber?

Anti-Interference Plastic Optical Fiber (POF) is a specialized type of optical fiber designed to minimize signal interference during data transmission. Unlike traditional glass-based optical fibers, POF uses plastic as the core material, making it more flexible, lightweight, and cost-effective. The anti-interference feature ensures that signals remain clear even in environments with high electromagnetic noise or crosstalk.

Key Features of Anti-Interference Plastic Optical Fiber

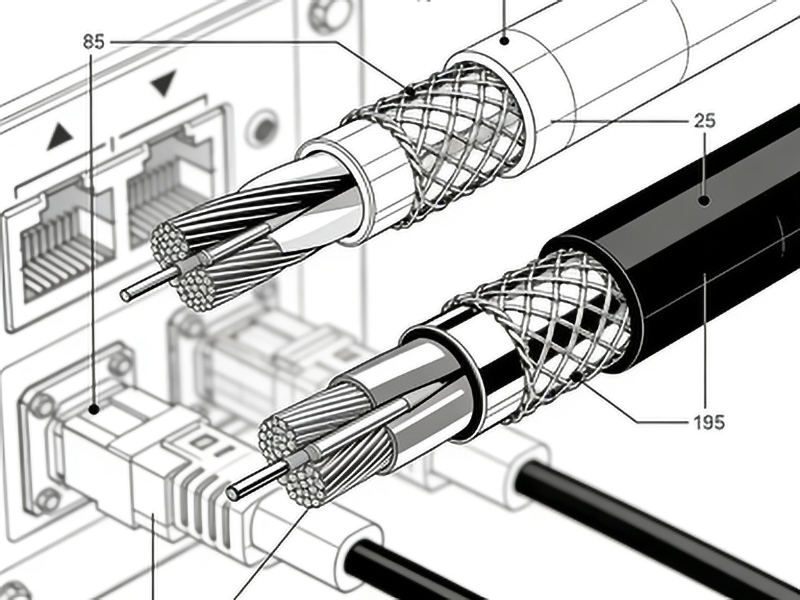

1. Material Composition: Made from plastic materials such as PMMA (Polymethyl Methacrylate) or other thermoplastic polymers, POF is more durable and flexible than glass fibers.

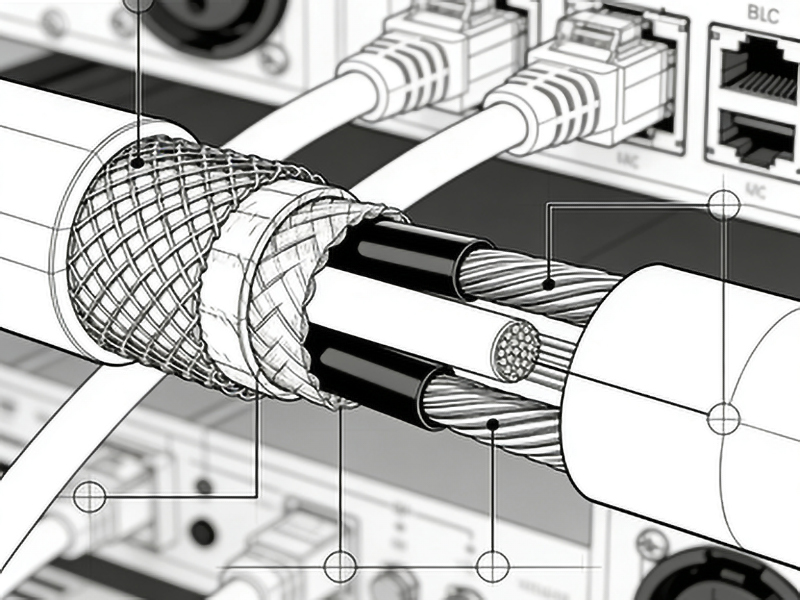

2. Anti-Interference Mechanism: Utilizes shielding techniques or specialized coatings to prevent signal degradation caused by external electromagnetic interference.

3. High Flexibility: The plastic core allows the fiber to bend without breaking, making it ideal for applications requiring frequent movement or installation in tight spaces.

4. Cost-Effective: Lower production costs compared to glass fibers make POF an economical choice for various industries.

5. Wide Temperature Range: Designed to operate efficiently across a broad temperature spectrum, ensuring reliability in diverse environments.

Technical Specifications

When considering anti-interference plastic optical fiber, several technical parameters are crucial:

– Core Diameter: Typically ranges from 0.3 mm to 1 mm, depending on the application requirements.

– Cladding Diameter: Usually between 0.5 mm and 2 mm, providing optimal light confinement within the core.

– Attenuation: Low attenuation rates ensure minimal signal loss over longer distances, typically ranging from 0.1 dB/km to a few dB/km depending on the fiber type.

– Numerical Aperture (NA): This measures the fiber’s ability to collect light and is usually around 0.4 to 0.6 for POF, which is higher than in glass fibers, allowing for easier coupling of light sources.

– Operating Wavelength: Typically supports visible wavelengths, making it suitable for specific applications like data transmission or illumination systems.

Benefits of Using Anti-Interference Plastic Optical Fiber

The advantages of anti-interference POF make it a preferred choice in various industries:

1. Reduced Signal Interference: The built-in shielding and specialized coatings minimize crosstalk and electromagnetic interference, ensuring high-quality signal transmission.

2. Enhanced Durability: The plastic material offers better resistance to environmental factors such as moisture, chemicals, and temperature fluctuations compared to glass fibers.

3. Ease of Installation: The flexibility and lightweight nature of POF make installation simpler and less labor-intensive, especially in challenging environments.

4. Cost Efficiency: Lower production costs result in more affordable solutions without compromising on performance.

5. Versatility: Suitable for a wide range of applications, from industrial automation to medical devices, anti-interference POF offers flexibility across industries.

Applications of Anti-Interference Plastic Optical Fiber

Anti-interference plastic optical fiber finds application in diverse fields due to its unique properties:

1. Telecommunications: Used in local area networks (LANs) and other communication systems requiring reliable data transmission with minimal interference.

2. Industrial Automation: Ideal for control systems in manufacturing plants where electromagnetic interference is a common issue.

3. Medical Devices: Employed in imaging systems and patient monitoring equipment to ensure accurate signal transmission in critical environments.

4. Automotive Industry: Utilized in vehicle communication networks (CAN buses) to enhance data integrity amidst high electromagnetic noise.

5. Avionics: Used in aircraft wiring systems to maintain reliable communication despite extreme conditions and interference.

6. Illumination Systems: Due to its ability to transmit visible light efficiently, POF is used in lighting applications such as architectural lighting and signage.

Challenges and Considerations

While anti-interference plastic optical fiber offers numerous benefits, there are challenges to consider:

1. Limited Bandwidth: Compared to glass fibers, POF has a lower bandwidth, making it less suitable for high-speed, long-distance communication networks.

2. Signal Loss Over Distance: Higher attenuation rates compared to glass fibers can lead to signal degradation over longer distances.

3. Temperature Sensitivity: While designed for wide temperature ranges, extreme temperatures can still affect performance and longevity.

4. Mechanical Durability: Although more flexible than glass fibers, POF may be susceptible to mechanical stress over time, especially in harsh environments.

5. Compatibility Issues: Ensuring proper coupling with light sources and receivers is crucial, as improper alignment can lead to signal loss or degradation.

Conclusion

Anti-Interference Plastic Optical Fiber represents a significant advancement in optical fiber technology, offering a blend of flexibility, durability, and interference resistance. Its ability to operate efficiently in challenging environments makes it an ideal solution for various industries seeking reliable data transmission without compromising on performance. As technology continues to evolve, anti-interference POF will likely find even more applications, solidifying its role as a key component in modern communication systems.