Introduction

Plastic Optical Fiber (POF) has emerged as a game-changer in the realm of consumer electronics. This innovative technology leverages light to transmit data, offering significant advantages over traditional copper-based solutions. In this article, we delve into the intricacies of POF, its applications, and why it’s poised to dominate the future of electronic communication.

What is Plastic Optical Fiber?

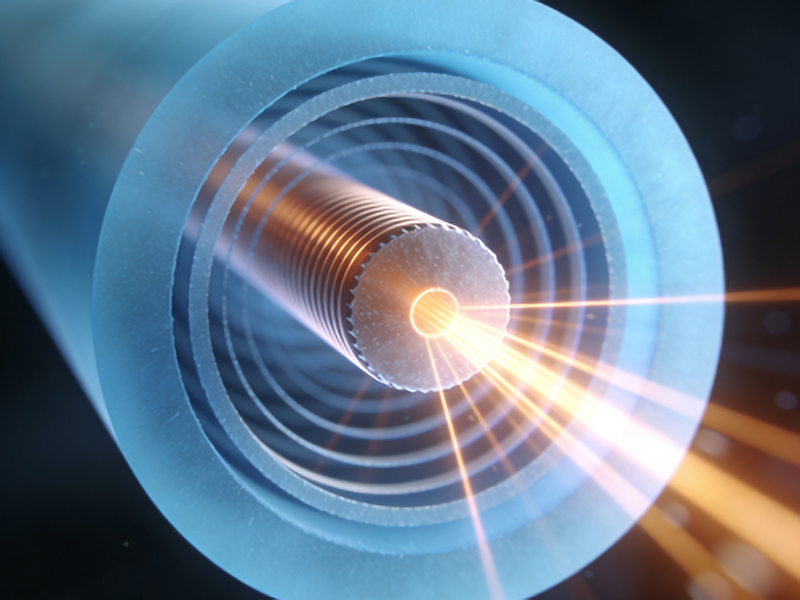

Plastic Optical Fiber (POF) is a type of optical fiber made from plastic materials rather than glass. Unlike traditional glass fibers, which are used primarily in telecommunications for high-speed data transmission over long distances, POF is designed for short-distance applications within consumer electronics. Its flexibility and ease of use make it an ideal choice for modern gadgets.

Technical Specifications

Core Diameter

The core diameter of POF typically ranges from 0.5mm to 1mm, which is significantly larger than that of glass fibers. This larger core allows for easier coupling of light sources, reducing the complexity and cost associated with alignment during manufacturing.

Cladding Material

POF uses a plastic cladding material with a lower refractive index than the core. Common materials include polymethyl methacrylate (PMMA) or polystyrene. The cladding ensures that light remains within the core through total internal reflection, enabling efficient data transmission.

Bandwidth and Speed

While POF doesn’t achieve the same bandwidth as glass fibers, it still offers sufficient performance for consumer electronics. Typical bandwidths range from 10 MHz to 500 MHz, with data rates up to several hundred megabits per second. This is more than adequate for applications like high-definition video transmission and peripheral connections.

Advantages of Plastic Optical Fiber

Cost-Effectiveness

One of the most significant advantages of POF is its lower cost compared to glass fibers. The manufacturing process for plastic materials is less complex and resource-intensive, making it an economical solution for mass-produced consumer electronics.

Flexibility and Durability

POF is highly flexible and resistant to bending, unlike fragile glass fibers. This flexibility allows for easier integration into the compact designs of modern electronics. Additionally, POF is less susceptible to environmental factors such as temperature fluctuations and humidity, making it reliable in diverse operating conditions.

Lightweight Design

The lightweight nature of plastic makes POF an excellent choice for reducing the overall weight of electronic devices. This is particularly beneficial for portable electronics like smartphones, tablets, and laptops, where minimizing weight is a critical design consideration.

Applications in Consumer Electronics

High-Definition Video Transmission

POF is widely used in high-definition video applications such as digital displays, televisions, and projectors. Its ability to handle high bandwidths ensures crisp, clear images without signal degradation.

Data Communication

In consumer electronics, POF enables fast and reliable data transfer between devices. Applications include connecting peripherals like printers, scanners, and external storage devices to computers or other electronic systems.

Automotive Electronics

The automotive industry is increasingly adopting POF for in-vehicle communication systems. Its resistance to electromagnetic interference (EMI) makes it ideal for use in cars where multiple electronic systems operate simultaneously.

Challenges and Limitations

While POF offers numerous benefits, it also has some limitations that need consideration:

1. Shorter Transmission Distance: Compared to glass fibers, POF has a shorter effective transmission range, typically up to 50 meters. This makes it unsuitable for long-distance applications.

2. Lower Bandwidth: The bandwidth of POF is lower than that of glass fibers, limiting its use in high-speed data transmission scenarios beyond consumer electronics.

3. Signal Loss Over Time: Over time, the optical properties of plastic can degrade due to UV exposure or temperature changes, leading to signal attenuation.

Future Trends and Innovations

The future of POF looks promising with ongoing advancements in material science and manufacturing techniques. Researchers are exploring ways to enhance the durability and bandwidth capabilities of POF, making it suitable for a broader range of applications.

Integration with IoT

As the Internet of Things (IoT) continues to expand, POF is expected to play a crucial role in connecting smart devices within homes and industries. Its cost-effectiveness and flexibility make it an ideal candidate for IoT applications.

Development of Micro-POF

Recent developments in micro-POF technology aim to reduce the core diameter while maintaining or improving performance. This innovation could pave the way for even more compact and efficient optical communication systems within consumer electronics.

Conclusion

Plastic Optical Fiber is revolutionizing the landscape of consumer electronics with its unique combination of cost-effectiveness, flexibility, and reliability. As technology continues to evolve, POF is set to become an integral part of future electronic devices, driving innovation and enhancing user experiences.