Introduction

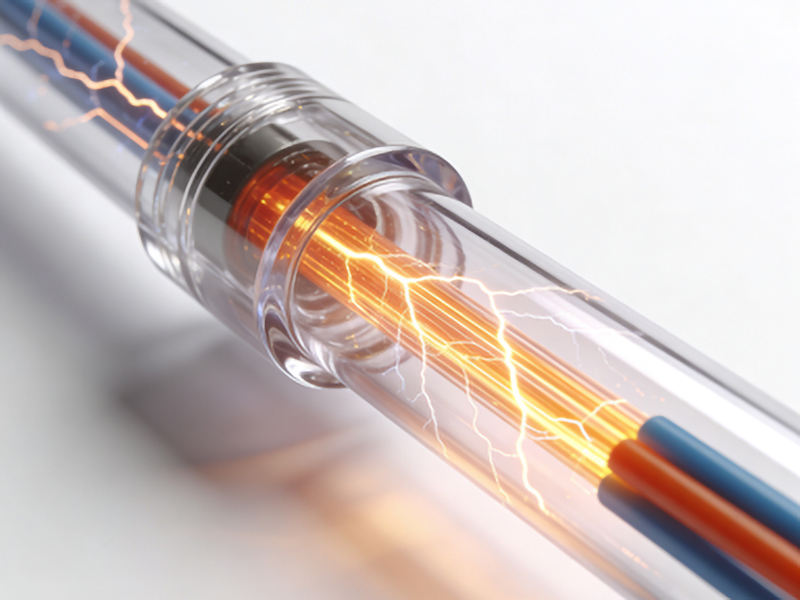

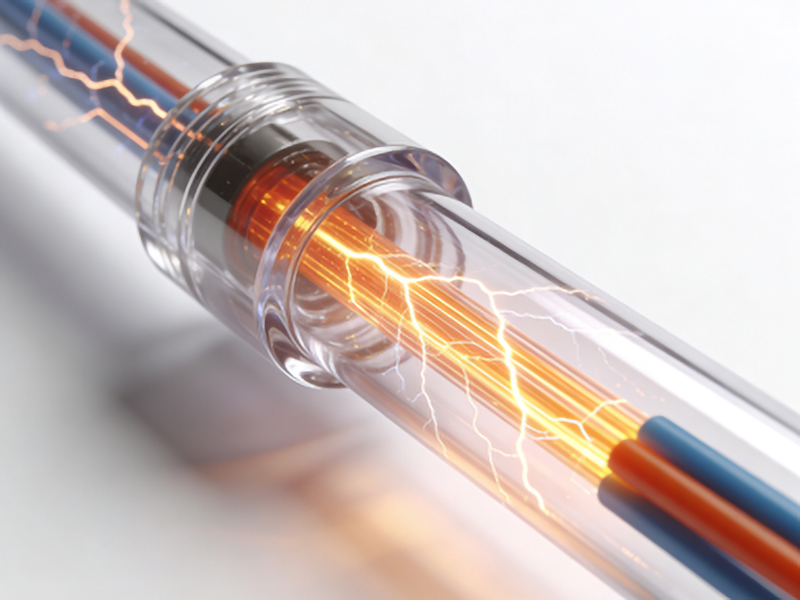

Lightning Protection Plastic Optical Fiber (LP-POF) is a specialized type of optical fiber designed to protect telecommunication networks from the devastating effects of lightning strikes. This article delves into the technical aspects, benefits, and applications of LP-POF, providing readers with a comprehensive understanding of its importance in modern telecommunications infrastructure.

What is Lightning Protection Plastic Optical Fiber?

Plastic Optical Fiber (POF) is a type of optical fiber made from plastic materials, as opposed to the more common silica-based glass fibers. POF is known for its flexibility and ease of use, making it ideal for short-distance communication applications such as in cars, homes, and industrial settings.

Lightning Protection Plastic Optical Fiber (LP-POF) integrates additional protective measures to safeguard against lightning-induced damage. Lightning strikes can cause voltage surges that disrupt or destroy electronic equipment connected to telecommunication networks. LP-POF is specifically engineered to mitigate these risks by incorporating materials and designs that dissipate lightning energy safely without compromising data transmission quality.

Technical Parameters of LP-POF

Understanding the technical specifications of LP-POF is crucial for selecting the appropriate solution for specific applications. Key parameters include:

1. Attenuation: The reduction in signal strength as light travels through the fiber. LP-POF typically has higher attenuation compared to glass fibers, making it suitable for shorter distances (up to a few hundred meters).

2. Bandwidth: The range of frequencies that can be transmitted effectively. LP-POF offers moderate bandwidth, sufficient for many telecommunications and industrial applications.

3. Diameter: Common diameters include 1 mm and 0.5 mm, which affect bending radius and flexibility.

4. Cladding Material: The outer layer that ensures total internal reflection of light signals. Advanced cladding materials in LP-POF enhance protection against environmental factors and lightning-induced stress.

5. Lightning Withstand Voltage: The maximum voltage the fiber can endure without damage, typically measured in kilovolts (kV). LP-POF is designed to withstand high voltages associated with lightning strikes.

Benefits of Lightning Protection Plastic Optical Fiber

LP-POF offers several advantages over traditional optical fibers and copper cables:

1. Enhanced Lightning Resistance: Specifically engineered to handle voltage surges from lightning, reducing the risk of network outages and equipment damage.

2. Cost-Effective Solution: POF is generally more affordable than glass fiber, making LP-POF an economical choice for protecting telecommunications infrastructure.

3. Ease of Installation: The flexibility and lightweight nature of POF simplify installation processes, especially in challenging environments.

4. Reduced Maintenance Requirements: Durable construction minimizes the need for frequent repairs or replacements, lowering long-term maintenance costs.

5. Improved Signal Integrity: Despite higher attenuation, LP-POF maintains reliable data transmission, ensuring consistent network performance.

Applications of Lightning Protection Plastic Optical Fiber

LP-POF finds application in various sectors where lightning protection is critical:

1. Telecommunications Networks: Protecting fiber-optic networks from lightning-induced damage, ensuring uninterrupted communication services.

2. Industrial Automation Systems: Safeguarding industrial control systems and automation equipment in outdoor or exposed environments.

3. Power Distribution Networks: Incorporating LP-POF in power line communication (PLC) systems to enhance reliability and safety.

4. Aviation and Maritime Industries: Protecting communication systems in aircraft and marine vessels from lightning strikes, which are common in these environments.

5. Smart Grid Infrastructure: Enhancing the resilience of smart grid systems against lightning-related disruptions.

Installation and Maintenance Considerations

To maximize the effectiveness of LP-POF, proper installation and maintenance practices should be followed:

1. Grounding Systems: Ensure that the fiber-optic network is properly grounded to provide a safe path for lightning-induced currents, minimizing damage to connected equipment.

2. Surge Protection Devices (SPDs): Install SPDs in conjunction with LP-POF to further mitigate voltage surges and protect sensitive electronics.

3. Environmental Sealing: Use appropriate sealing techniques to prevent moisture ingress, which can degrade fiber performance over time.

4. Regular Inspections: Periodically inspect LP-POF installations for any signs of physical damage or environmental stress that could compromise their protective qualities.

5. Compliance with Standards: Adhere to relevant industry standards and regulations when designing and implementing LP-POF solutions to ensure optimal performance and safety.

Conclusion

Lightning Protection Plastic Optical Fiber is a vital component in safeguarding telecommunications and industrial networks against the destructive effects of lightning strikes. By combining the flexibility and affordability of POF with advanced protective features, LP-POF offers an effective solution for maintaining network reliability and equipment integrity. As lightning remains one of the most significant threats to outdoor communication systems, investing in LP-POF technology is essential for ensuring uninterrupted service delivery and minimizing potential downtime and repair costs.