Understanding PMMA Plastic Optical Fiber: Applications and Technical Insights

Poly(methyl methacrylate), commonly known as PMMA, is a key material used in the production of plastic optical fibers. These fibers play an integral role in various applications across industries, from telecommunications to sensing technologies.

What is PMMA Plastic Optical Fiber?

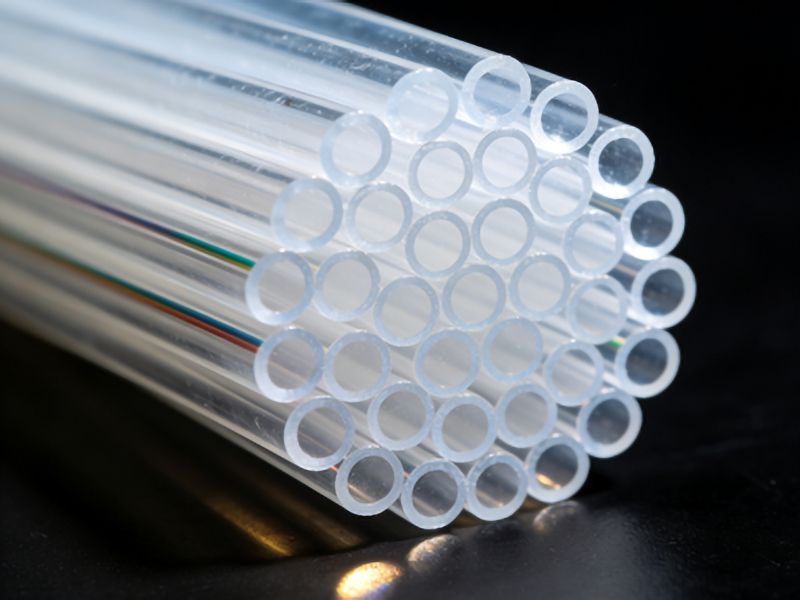

Plastic optical fibers (POFs) made from PMMA are designed for efficient light propagation over short distances. Unlike traditional silica-based optical fibers, PMMA POFs offer unique advantages such as flexibility and ease of handling, making them ideal for specific use cases.

Key Properties of PMMA Plastic Optical Fibers

1. Core Material: The core is made from high-purity PMMA, ensuring optimal light transmission characteristics.

2. Cladding Layer: Typically surrounded by a cladding layer that maintains the fiber’s structure and enhances durability.

3. Attenuation: Lower attenuation compared to other polymer-based fibers, allowing for longer signal transmission without significant loss.

4. Flexibility: Highly flexible, enabling easy installation in diverse environments.

5. Temperature Resistance: Operates effectively within a wide temperature range, suitable for various industrial settings.

Technical Specifications and Parameters

– Diameter: Ranges from 0.5 mm to several millimeters, depending on the application requirements.

– Numerical Aperture (NA): Typically between 0.45 to 0.55, indicating a wide acceptance angle for efficient light capture.

– Attenuation Coefficient: Approximately 1 dB/m at visible wavelengths, making it suitable for short-distance communication.

– Bandwidth: Supports data rates up to several Gbps, depending on the fiber’s design and application.

Applications of PMMA Plastic Optical Fibers

PMMA POFs find applications in a variety of fields due to their unique properties:

1. Telecommunications: Used for short-distance, high-speed data transmission within buildings or campuses.

2. Sensing Technologies: Employed in fiber-optic sensors for temperature, strain, and other environmental measurements.

3. Medical Devices: Utilized in endoscopes and minimally invasive surgical tools for their flexibility and imaging capabilities.

4. Automotive Industry: Integrated into vehicles for data transmission in infotainment systems and sensor networks.

5. Industrial Automation: Applied in harsh environments for monitoring and control systems where traditional fibers might fail.

Advantages of PMMA Plastic Optical Fibers

– Cost-Effective: Lower production costs compared to silica-based fibers, making them a viable option for cost-sensitive applications.

– Ease of Use: Simpler installation processes due to flexibility and compatibility with standard connectors.

– Durability: Resistant to environmental factors such as moisture and chemicals, ensuring long-term reliability.

Challenges and Limitations

While PMMA POFs offer numerous benefits, they also have certain limitations:

1. Distance Limitation: Suitable only for short-distance transmissions due to higher attenuation compared to silica fibers.

2. Bandwidth Constraints: Lower bandwidth capabilities make them less suitable for high-speed, long-haul communication networks.

3. Temperature Sensitivity: While PMMA offers good temperature resistance, extreme conditions can affect performance.

Conclusion

PMMA plastic optical fibers represent a versatile and cost-effective solution for various applications where short-distance, high-speed data transmission is required. Their flexibility, durability, and ease of use make them an invaluable component in modern communication and sensing systems. As technology continues to evolve, PMMA POFs are expected to play a pivotal role in innovative solutions across multiple industries.