Introduction to Ultrasonic Polymerization POF

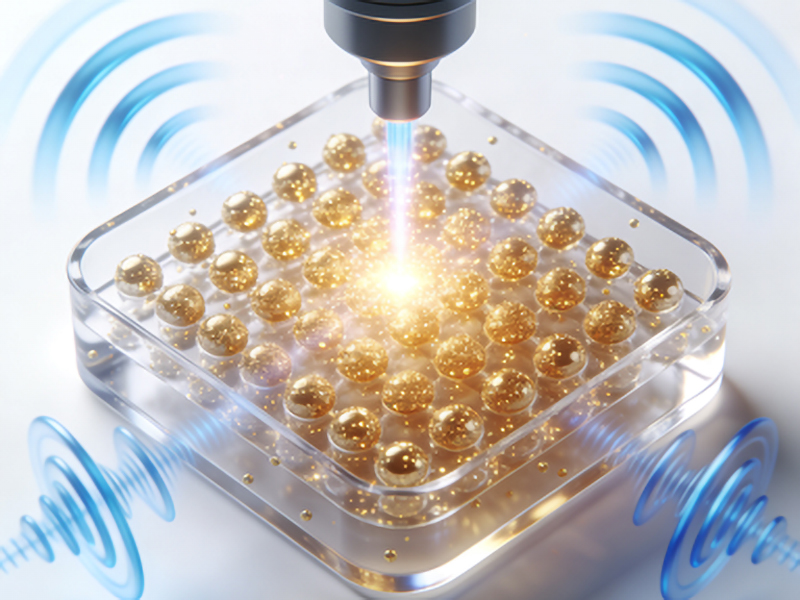

Ultrasonic polymerization, often abbreviated as POF (Polymerization by Oscillating Fields), is an advanced technique that leverages ultrasonic energy to facilitate the formation of polymers. This method has gained significant attention in recent years due to its ability to offer precise control over the polymerization process, leading to higher quality materials and more efficient manufacturing processes.

Technical Overview

Principle of Operation

Ultrasonic polymerization involves the application of high-frequency sound waves (typically in the range of 20 kHz to 100 kHz) to initiate and control the polymerization reaction. The ultrasonic energy generates mechanical vibrations within the polymer material, creating a localized environment conducive to molecular bonding and chain growth.

Key Parameters

– Frequency: 20 kHz to 100 kHz

– Power Density: 0.5 W/cm² to 3 W/cm²

– Temperature Control: Maintained between 40°C to 80°C

– Processing Time: Varies from 10 seconds to several minutes depending on polymer type and desired properties

Advantages of POF Technology

1. Precision Control: The ability to precisely control the ultrasonic parameters allows for tailored polymer structures with specific mechanical, thermal, and electrical properties.

2. Energy Efficiency: Compared to traditional methods, POF requires less energy input due to its targeted application of ultrasonic waves.

3. Reduced Material Waste: By optimizing the polymerization process, POF minimizes material waste and enhances yield rates.

4. Scalability: Suitable for both small-scale laboratory applications and large-scale industrial production.

Applications in Manufacturing

Polymer Blending

Ultrasonic polymerization is particularly effective in blending different polymers to create composite materials with enhanced properties. For instance, combining thermoplastics with elastomers can result in materials that are both strong and flexible.

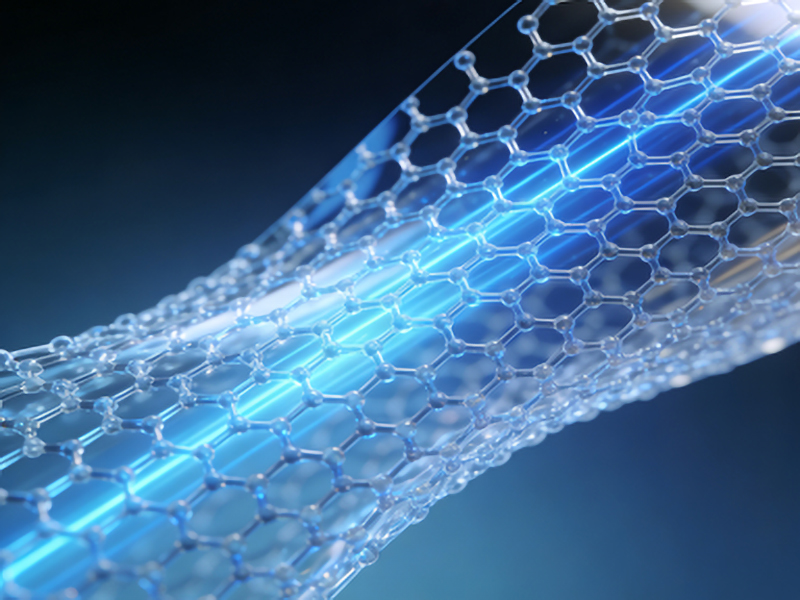

Nanoparticle Incorporation

The high-energy environment created by ultrasonic waves facilitates the incorporation of nanoparticles into polymer matrices. This enables the creation of nanocomposites with improved mechanical strength, thermal stability, and conductivity.

Surface Modification

POF technology can be used to modify the surface properties of polymers, such as increasing hydrophilicity or enhancing adhesion without affecting the bulk material’s properties.

Challenges and Considerations

While ultrasonic polymerization offers numerous benefits, there are challenges that need to be addressed:

1. Equipment Cost: The initial investment in high-quality ultrasonic equipment can be significant.

2. Process Optimization: Achieving optimal results requires careful tuning of parameters such as frequency, power density, and temperature.

3. Material Compatibility: Not all polymers are suitable for POF technology; compatibility must be assessed on a case-by-case basis.

Future Trends and Innovations

The field of ultrasonic polymerization is continuously evolving with advancements in ultrasonic transducer design, real-time monitoring systems, and smart control algorithms. Researchers are also exploring the use of multi-frequency ultrasound to further enhance process efficiency and material properties.

Conclusion

Ultrasonic polymerization POF represents a cutting-edge approach to polymer manufacturing, offering precise control, energy efficiency, and scalability. As technology advances and becomes more accessible, POF is expected to play an increasingly important role in the development of advanced materials for various industries.