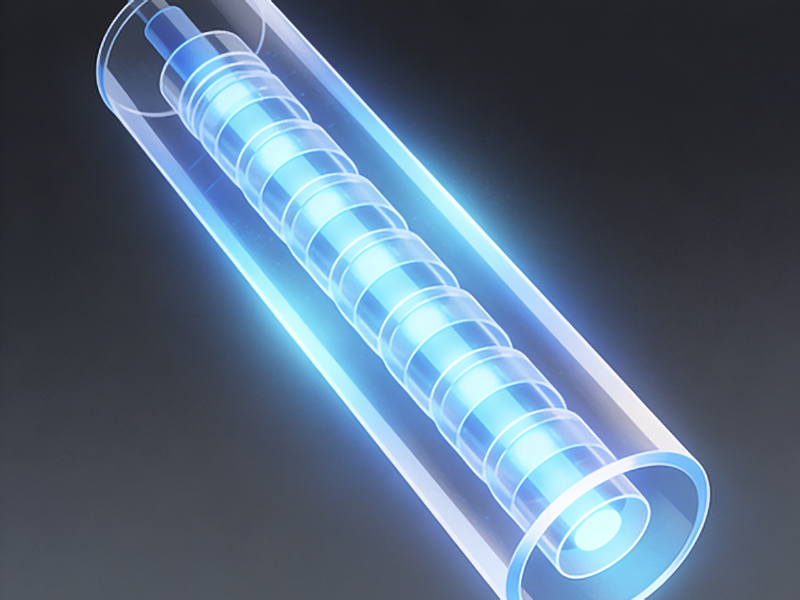

What is Solid-Core Side-Glow POF?

Solid-core side-glow POF (Plastic Optical Fiber) is an innovative optical fiber technology designed to emit light along the length of the fiber, creating a uniform glow effect. Unlike traditional end-emitting fibers, solid-core side-glow POF distributes light evenly across its surface, making it ideal for applications where diffuse lighting is required.

Key Features

– Uniform Light Distribution: The core is solid, allowing light to scatter throughout the fiber and emit from the sides, resulting in a consistent glow without hot spots.

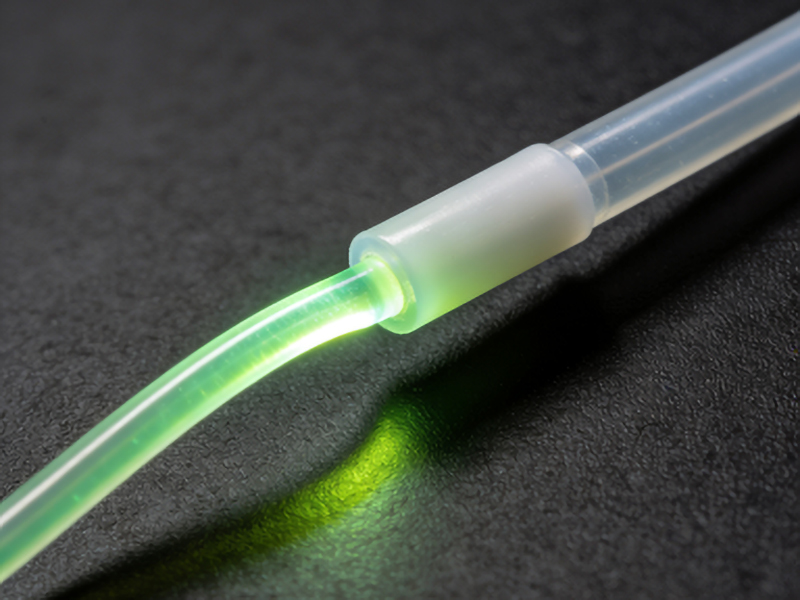

– High Flexibility: Solid-core side-glow POF is highly flexible, enabling it to be bent into various shapes without affecting performance.

– Durability: Constructed with high-quality materials, this type of POF is resistant to environmental factors and mechanical stress.

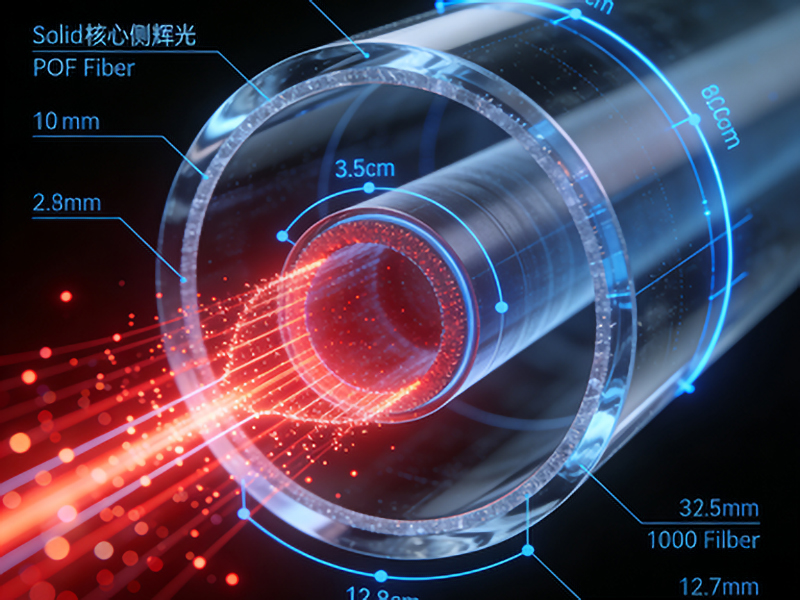

Technical Specifications

When selecting solid-core side-glow POF, consider the following parameters:

– Core Diameter: Typically ranges from 0.5mm to 1.0mm, affecting light intensity and flexibility.

– Cladding Thickness: Usually between 25μm to 75μm, which impacts light retention and overall durability.

– Flexibility Radius: The minimum radius the fiber can bend without damage, often specified in millimeters (e.g., 10mm).

Applications

Solid-core side-glow POF finds application in various industries:

1. Automotive Lighting: Used for interior lighting, such as door handles and trim accents.

2. Aviation: Applied in cabin lighting to create a soft, diffused glow.

3. Architectural Lighting: Ideal for creating decorative accents in buildings, walkways, and public spaces.

4. Medical Equipment: Employed in devices where uniform lighting is essential for accurate observation.

5. Consumer Electronics: Utilized in displays and aesthetic lighting features.

Advantages of Solid-Core Side-Glow POF

– Energy Efficiency: Low power consumption compared to traditional lighting solutions.

– Design Flexibility: Can be easily shaped and integrated into various designs.

– Longevity: High durability ensures a longer lifespan, reducing maintenance costs.

Installation and Maintenance

Proper installation is crucial for optimal performance:

1. Preparation: Ensure the fiber is clean and free from contaminants before use.

2. Bending Radius: Adhere to the recommended flexibility radius to prevent damage.

3. Sealing: Use appropriate sealing materials to protect the fiber from environmental factors.

4. Testing: Conduct regular checks to ensure consistent light output and functionality.

Challenges and Considerations

– Light Loss: Over time, minor light loss can occur due to environmental exposure or mechanical stress.

– Temperature Sensitivity: Some materials may degrade under extreme temperatures, affecting performance.

– Compatibility: Ensure the fiber is compatible with the lighting source and other components in the system.

Future Trends

The demand for solid-core side-glow POF is expected to grow as industries seek energy-efficient and flexible lighting solutions. Innovations in material science are likely to enhance durability and light efficiency, expanding its application across more sectors.

Conclusion

Solid-core side-glow POF offers a versatile and efficient solution for modern lighting needs. Its ability to distribute light uniformly and adapt to various design requirements makes it an invaluable component in numerous industries. By understanding its features, applications, and proper handling, professionals can harness the full potential of this innovative technology.