Introduction

Plastic Optical Fiber (POF) is an innovative solution that leverages plastic materials to transmit light signals over distances, offering several benefits over traditional glass-based optical fibers. This article delves into the POF system, examining its components, advantages, applications, and key considerations for implementation.

Components of a Plastic Optical Fiber System

A typical POF system comprises the following essential components:

1. Optical Fiber Cables: Made from high-quality plastic materials, these cables are designed to efficiently guide light signals with minimal loss.

2. Light Sources: Typically LEDs or laser diodes, these devices generate the optical signals for transmission.

3. Connectors and Adapters: These ensure secure connections between fiber cables and other system components.

4. Receivers: Devices that convert the received light signals back into electrical signals.

5. Couplers and Splitters: Used to combine or split light signals within the network.

Advantages of POF Systems

Plastic Optical Fiber systems offer numerous advantages, making them an attractive choice for various applications:

– Cost-Effective: Plastic fibers are generally cheaper than their glass counterparts due to lower production costs.

– Ease of Use: The flexibility and durability of plastic fibers make installation and maintenance easier.

– Signal Integrity: POF systems maintain high signal quality over longer distances, reducing the need for repeaters or amplifiers.

– Resistance to Interference: Plastic fibers are immune to electromagnetic interference (EMI), ensuring reliable data transmission in noisy environments.

Technical Parameters of POF Systems

Understanding the technical specifications is crucial for designing and implementing effective POF systems. Key parameters include:

– Attenuation: The reduction in signal strength as light travels through the fiber, typically measured in dB/km.

– Bandwidth: The range of frequencies over which the system can effectively transmit data, critical for high-speed applications.

– Connector Loss: The loss of signal at connection points, often due to misalignment or poor mating.

– Temperature Range: The operating temperature limits of the fiber and associated components.

Applications of Plastic Optical Fiber Systems

POF systems find application in diverse industries, including:

– Telecommunications: For local area networks (LANs) and data centers requiring high-speed, reliable connections.

– Industrial Automation: Used in harsh environments for control systems and machine-to-machine communication.

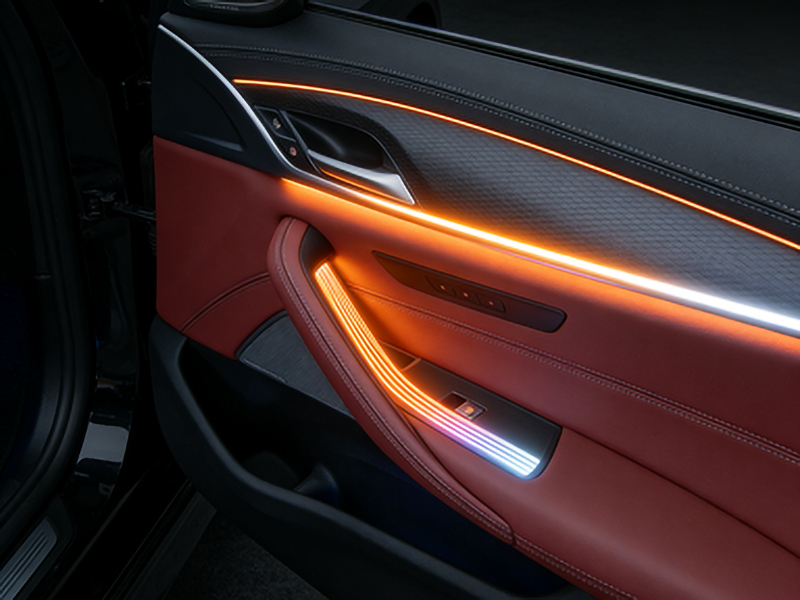

– Automotive Industry: Employed in vehicles for data transmission between subsystems such as infotainment and sensor networks.

– Medical Devices: Ideal for use in medical equipment where EMI resistance is crucial.

Challenges and Considerations

While POF systems offer many benefits, there are challenges to consider:

– Distance Limitations: Compared to glass fibers, plastic fibers have higher attenuation, limiting transmission distances.

– Connector Quality: The integrity of connections significantly affects performance; high-quality connectors are essential.

– Environmental Factors: Temperature extremes and physical stress can impact the fiber’s performance over time.

Conclusion

Plastic Optical Fiber systems present a viable, cost-effective alternative to traditional optical solutions. Their ease of use, resistance to interference, and versatility across various applications make them an attractive choice for modern communication needs. By understanding their technical parameters and addressing potential challenges, organizations can harness the full potential of POF systems in their networking infrastructure.