Introduction

Plastic Optical Fibers (POFs) have emerged as a game-changing technology in the field of fiber optics. Unlike traditional silica-based optical fibers, POFs utilize polymer materials, offering unique advantages such as flexibility, ease of handling, and cost-effectiveness. However, conventional POFs often face challenges related to mechanical strength and durability, limiting their broader adoption. This is where High-Toughness Plastic Optical Fibers (HT-POFs) come into play, addressing these limitations while retaining the inherent benefits of plastic fibers.

Properties of High-Toughness Plastic Optical Fiber

1. Mechanical Strength: HT-POFs exhibit exceptional resistance to breakage and deformation under mechanical stress. This is achieved through advanced polymer formulations that enhance the material’s toughness without compromising its optical properties.

2. Optical Clarity: Despite their high toughness, these fibers maintain excellent light transmission capabilities, ensuring minimal signal loss over long distances.

3. Flexibility: HT-POFs remain highly flexible, allowing for easy installation and routing in complex environments.

4. Durability: Enhanced durability against environmental factors such as temperature fluctuations and UV exposure further underscores their suitability for a wide range of applications.

5. Cost-Effective: Compared to silica-based fibers, HT-POFs offer a more economical solution without sacrificing performance.

Technical Parameters

The performance of High-Toughness Plastic Optical Fibers is characterized by several key technical parameters:

1. Numerical Aperture (NA): This measures the fiber’s ability to collect light. A higher NA indicates greater acceptance of incoming light, enhancing signal strength. Typical values for HT-POFs range from 0.4 to 0.6.

2. Attenuation: The reduction in signal intensity as light travels through the fiber is measured in decibels per kilometer (dB/km). HT-POFs typically exhibit lower attenuation compared to standard POFs, often around 1 dB/km at specific wavelengths.

3. Bandwidth: This refers to the range of frequencies that can be transmitted through the fiber. HT-POFs support higher bandwidths, enabling faster data transmission rates.

4. Temperature Resistance: These fibers are designed to withstand temperature variations, with operating ranges often exceeding 80°C, making them suitable for harsh environments.

5. Tensile Strength: The ability to resist breaking under tension is significantly improved in HT-POFs, typically achieving tensile strengths above 100 MPa.

Applications of High-Toughness Plastic Optical Fiber

The enhanced properties of HT-POFs open up a wide array of applications across various industries:

1. Data Communication: Used in local area networks (LANs) and industrial communication systems for efficient data transmission with low latency.

2. Sensing Technologies: Incorporated into sensors for strain, temperature, and pressure measurements due to their high sensitivity and durability.

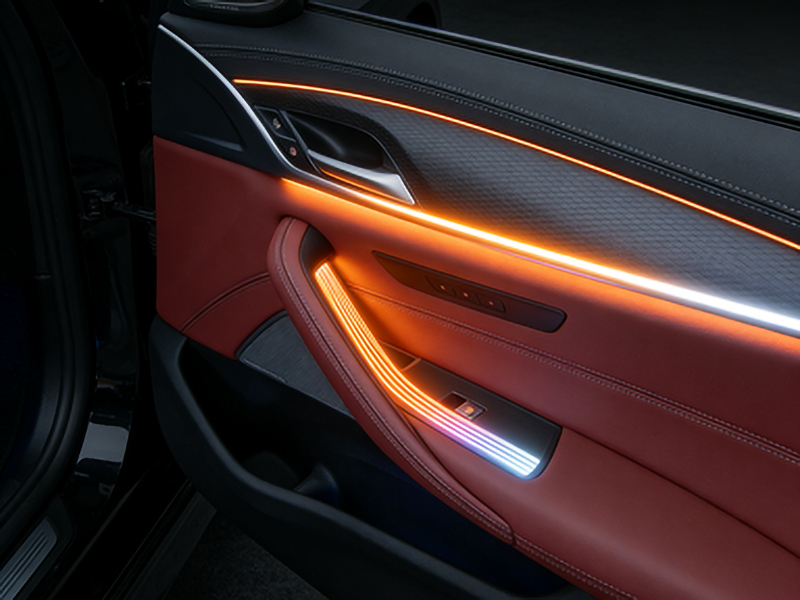

3. Automotive Industry: Applied in vehicle communication networks, offering lightweight solutions with superior mechanical strength.

4. Medical Field: Utilized in endoscopic devices where flexibility and high-toughness are critical for patient safety.

5. Industrial Automation: Employed in harsh industrial environments for reliable data transmission and monitoring systems.

Advancements in High-Toughness Plastic Optical Fiber Technology

The development of HT-POFs has been driven by advancements in polymer science and manufacturing techniques:

1. Polymer Blending: Combining different polymers to achieve a balance between mechanical strength, flexibility, and optical performance.

2. Nanotechnology: Incorporating nanomaterials such as carbon nanotubes or graphene to enhance the fiber’s mechanical properties without affecting its optical clarity.

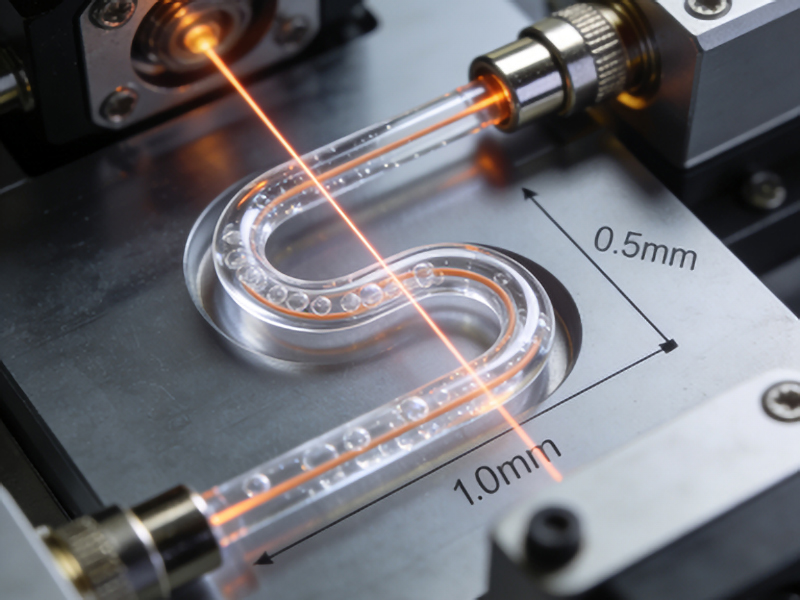

3. Laser Machining: Advanced fabrication methods using lasers for precise hole drilling and shaping, improving the overall efficiency of the fibers.

4. Surface Treatments: Applying coatings that provide additional protection against environmental factors while maintaining the fiber’s flexibility.

5. Smart Manufacturing: Leveraging AI and machine learning to optimize production processes, ensuring consistent quality and performance in HT-POFs.

Challenges and Future Directions

Despite their advantages, HT-POFs still face certain challenges:

1. Signal Loss at High Frequencies: While improvements have been made, there is room for further enhancement in maintaining signal integrity over longer distances at higher frequencies.

2. Cost of Production: The integration of advanced materials and manufacturing techniques can increase production costs, though economies of scale are expected to mitigate this over time.

3. Standardization: Establishing universal standards for HT-POF performance and testing protocols is crucial for widespread adoption and compatibility across different systems.

Looking ahead, research is focused on:

1. Developing New Polymers: Exploring novel polymer formulations that offer even higher mechanical strength without sacrificing optical properties.

2. Miniaturization: Reducing the diameter of HT-POFs to increase data transmission speeds while maintaining their toughness and flexibility.

3. Integration with IoT: Enhancing compatibility with Internet of Things (IoT) devices to support smart systems and real-time data processing.

4. Sustainability: Investigating eco-friendly production methods and recyclable materials to reduce the environmental impact of HT-POFs.

Conclusion

High-Toughness Plastic Optical Fibers represent a significant leap forward in fiber optic technology, offering a blend of mechanical strength, flexibility, and optical performance that makes them ideal for a wide range of applications. As advancements continue to address current limitations and expand their capabilities, HT-POFs are poised to play an increasingly important role in the future of communication and sensing technologies.