Plastic Optical Fiber Preparation Technology

Plastic optical fibers (POFs) have become an essential component in modern optical communication systems, offering a cost-effective and flexible alternative to traditional glass-based fibers. The preparation of POFs involves a series of precise steps that ensure optimal performance, durability, and reliability. This article delves into the key technologies and processes involved in preparing plastic optical fibers, highlighting their significance in the telecom industry.

1. Overview of Plastic Optical Fibers

Plastic optical fibers are made from thermoplastic materials such as polymethyl methacrylate (PMMA) or other acrylic-based polymers. These materials are chosen for their excellent light transmission properties and ease of processing. Unlike glass fibers, POFs are more flexible, easier to handle, and less prone to breakage, making them ideal for short-distance communication applications.

2. Key Preparation Steps

The preparation of plastic optical fibers typically involves the following steps:

a. Material Selection and Purification

The choice of raw materials is critical in determining the quality and performance of POFs. High-purity polymers are essential to minimize light attenuation and ensure consistent fiber properties. Advanced purification techniques, such as solvent extraction and filtration, are employed to remove impurities and enhance the optical clarity of the material.

b. Polymer Extrusion

The extrusion process is a critical step in POF manufacturing. The polymer resin is heated and forced through a die to form a cylindrical preform. Precision control over temperature, pressure, and cooling rates ensures uniform fiber diameter and optimal refractive index distribution.

c. Fiber Drawing

After the preform is produced, it undergoes the drawing process where it is stretched into long, thin fibers. This step requires precise control of tension and heating to achieve the desired fiber dimensions (typically in the range of 0.5 to several millimeters). The refractive index profile is carefully managed during this stage to optimize light transmission.

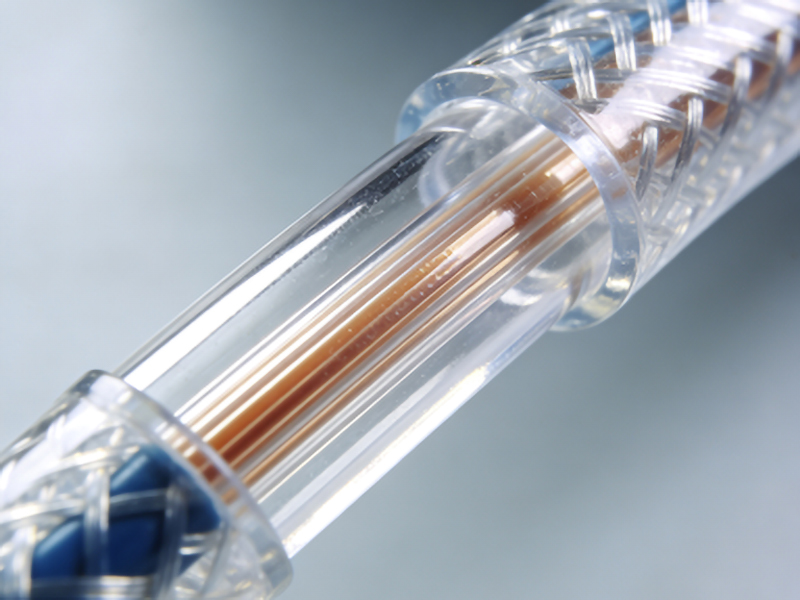

d. Coating Application

To protect the fragile optical fiber core, a protective coating is applied. This coating not only provides mechanical strength but also improves moisture resistance and flexibility. Common materials for coatings include acrylate polymers and silicone-based compounds.

3. Technical Parameters and Performance Indicators

Several technical parameters are crucial in evaluating the performance of plastic optical fibers:

– Fiber Diameter: Typically ranges from 0.5 mm to 1 mm, affecting signal transmission efficiency.

– Refractive Index (n): Usually around 1.49 for PMMA-based POFs, influencing light propagation characteristics.

– Attenuation Coefficient (α): Measures the reduction in光 intensity per unit length, typically ranging from 0 to 2 dB/m for high-quality POFs.

– Numerical Aperture (NA): Indicates the fiber’s ability to collect light, with values around 0.5 for most POFs.

– Bend Radius: Defines the minimum radius the fiber can bend without performance degradation, typically between 15 mm and 20 mm.

4. Applications of Plastic Optical Fibers

Plastic optical fibers find applications in a wide range of fields due to their unique properties:

– Telecommunications: Used for short-distance data transmission within buildings or campuses.

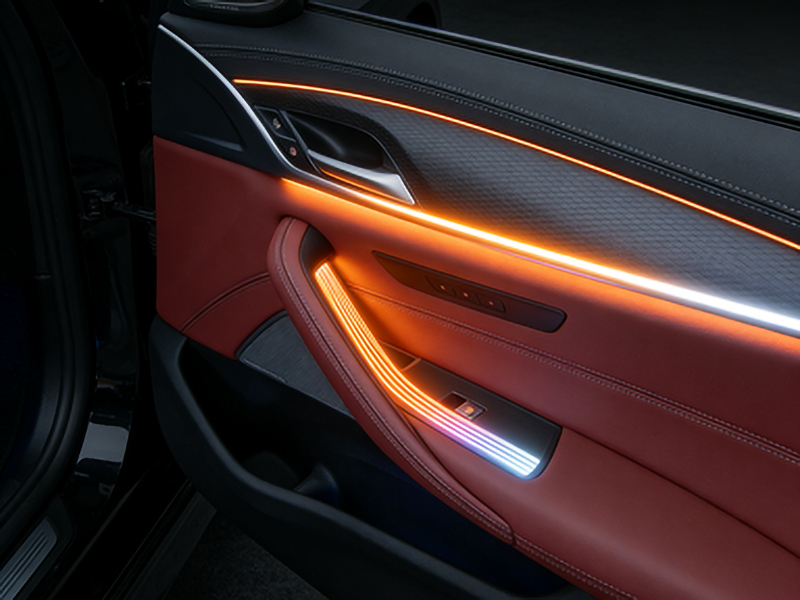

– Automotive Industry: Employed in vehicle communication networks (e.g., LIN bus systems).

– Medical Devices: Applied in endoscopes and other medical imaging tools.

– Illumination Systems: Utilized for decorative lighting and signage applications.

5. Challenges and Future Directions

Despite their advantages, POFs face challenges such as higher attenuation compared to glass fibers and limited bandwidth capabilities. Ongoing research is focused on improving material formulations, enhancing manufacturing precision, and developing hybrid fiber structures to overcome these limitations.

a. Advances in Material Science

Innovations in polymer chemistry are leading to the development of new materials with improved optical properties and thermal stability. For instance, fluoropolymer-based POFs show promise for higher temperature applications.

b. Nanotechnology Integration

The incorporation of nanoparticles into the fiber structure can enhance light transmission efficiency and reduce attenuation. Techniques such as nanocoating and nanocomposite formation are being explored to achieve these improvements.

c.智能制造 (Smart Manufacturing)

Adoption of smart manufacturing technologies, including AI-driven quality control and real-time process monitoring, is expected to improve production consistency and fiber performance.

6. Conclusion

The preparation technology for plastic optical fibers is a critical area of research and development in the telecom industry. By understanding the key steps, technical parameters, and future trends, manufacturers can continue to enhance POF performance and expand their applications in various sectors. As technology advances, POFs are likely to play an even more significant role in meeting the growing demands for efficient and reliable optical communication systems.