Introduction

Plastic Optical Fiber (POF) represents a groundbreaking advancement in optical communication technology. Unlike traditional glass-based fibers, POF utilizes polymer materials, offering a range of benefits that make it an excellent choice for various applications.

Technical Overview

Composition

Plastic Optical Fiber is primarily composed of high-quality polymers such as PMMA (Polymethyl Methacrylate) or other thermoplastic materials. These materials provide excellent light transmission properties while maintaining flexibility and durability.

Key Features

– High Transmission Efficiency: Despite being made from plastic, POF achieves impressive signal clarity and low attenuation over short to medium distances.

– Cost-Effective: The production process for POF is less complex compared to glass fibers, leading to lower costs without compromising performance.

– Ease of Installation: Its flexibility allows for easy routing in confined spaces and irregular pathways, making it ideal for installations where traditional glass fibers are challenging to deploy.

Technical Parameters

Here are some critical technical parameters that define the performance of Plastic Optical Fiber:

– Cladding Diameter: Typically ranges from 900 µm to 1 mm, providing a larger core size compared to glass fibers for easier coupling.

– Numerical Aperture (NA): Usually around 0.5, which allows for wider acceptance angles and simpler alignment during connections.

– Attenuation: Approximately 2 dB/m at wavelengths commonly used in communication systems, ensuring reliable signal transmission over short distances.

Applications

Plastic Optical Fiber is finding applications across multiple sectors:

1. Data Centers: Used for high-speed data transmission within server racks and interconnects due to its low latency and flexibility.

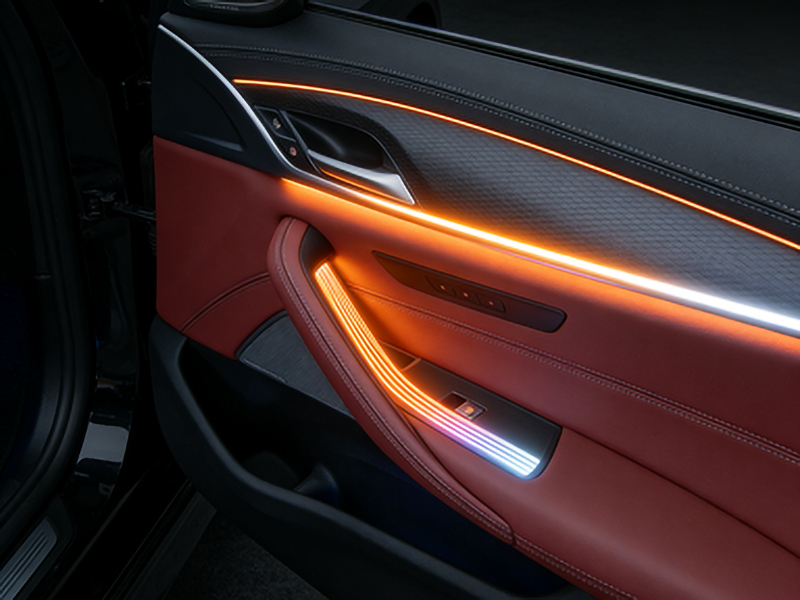

2. Automotive Industry: Incorporated into vehicle networks for data communication between sensors, control units, and entertainment systems.

3. Medical Equipment: Applied in endoscopes and imaging devices where flexible, lightweight fibers are essential.

4. Industrial Automation: Employed in industrial robots and automation systems for real-time data transmission under harsh conditions.

Advantages Over Traditional Fibers

– Lower Cost: Significantly cheaper than glass fibers due to simpler manufacturing processes and less stringent raw material requirements.

– Higher Flexibility: Capable of bending without signal loss, making it suitable for complex routing in confined spaces.

– Simplified Installation: Requires less specialized equipment and expertise compared to traditional fiber installations.

Challenges and Limitations

While POF offers many advantages, there are challenges that need to be addressed:

1. Distance Limitation: Higher attenuation rates make it unsuitable for long-distance communication beyond a few kilometers.

2. Bandwidth Constraints: Lower bandwidth capacity compared to glass fibers limits its use in high-speed, large-scale networks.

3. Temperature Sensitivity: Some polymer materials may degrade under extreme temperatures, affecting performance over time.

Future Prospects

The future of Plastic Optical Fiber looks promising with ongoing research and development focusing on:

– Improved Materials: Developing new polymer formulations to enhance transmission efficiency and thermal stability.

– Advanced Manufacturing Techniques: Innovations in production processes to reduce costs further while improving fiber quality.

– Expanded Applications: Exploring new use cases in emerging fields such as smart cities, IoT devices, and renewable energy systems.

Conclusion

Plastic Optical Fiber stands out as an innovative solution in the field of optical communication. Its unique combination of cost-effectiveness, flexibility, and ease of installation makes it a valuable addition to modern communication infrastructure. As technology continues to evolve, POF is expected to play a crucial role in meeting the growing demands for high-speed data transmission in various industries.