The Role of Plastic Optical Fiber in Automobile Manufacturing

Plastic optical fiber (POF) has emerged as a transformative technology in the automotive industry, offering significant advantages over traditional copper wiring. This article delves into the applications, benefits, and technical aspects of POF in automobile manufacturing.

What is Plastic Optical Fiber?

Plastic optical fiber is an optical medium made from plastic materials, typically polymethyl methacrylate (PMMA). Unlike its glass counterpart, POF is flexible, lightweight, and cost-effective, making it ideal for various automotive applications.

Key Technical Parameters of Plastic Optical Fiber

– Core Diameter: Usually ranges between 50 μm to 1 mm, depending on the application requirements.

– Cladding Thickness: Varies from 20 μm to 500 μm to ensure efficient light transmission.

– Numerical Aperture (NA): Typically in the range of 0.4 to 0.6, indicating the fiber’s ability to capture and transmit light.

– Attenuation: Around 10 dB/km at visible wavelengths, which is higher than glass fibers but sufficient for short-distance applications within vehicles.

Applications of Plastic Optical Fiber in Automobiles

1. Vehicle Networking Systems

POF plays a crucial role in vehicle networking by enabling high-speed data transmission between different modules. This includes communication between the engine control unit (ECU), infotainment systems, and sensors.

– Advantages:

– Reduced electromagnetic interference (EMI) compared to copper wires.

– Lightweight, contributing to overall vehicle weight reduction.

– Cost-effective solution for short-distance data transmission within vehicles.

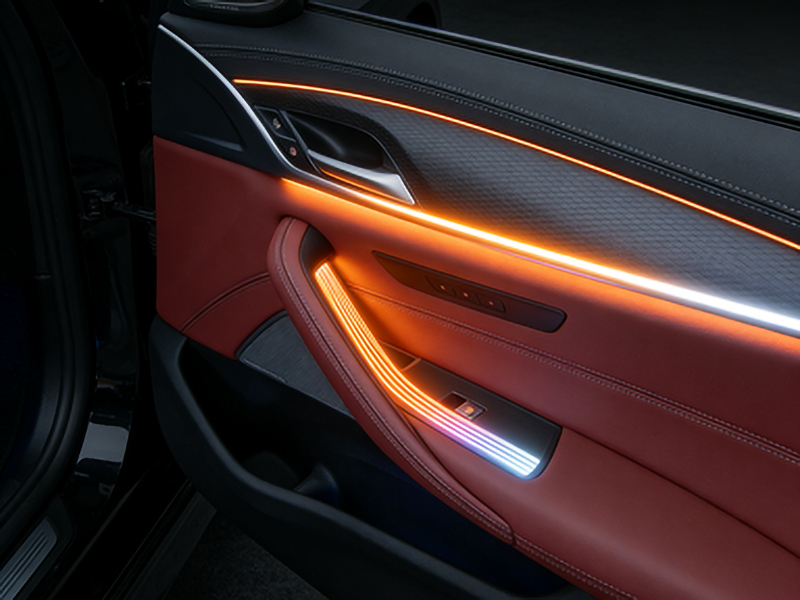

2. Lighting Systems

POF is increasingly used in lighting applications such as LED backlighting in dashboards and interior lights. The fiber’s flexibility allows for intricate designs without compromising on light distribution efficiency.

– Benefits:

– Enhanced design flexibility with minimal space requirements.

– Reduced energy consumption due to efficient light transmission.

– Longer lifespan compared to traditional lighting solutions.

3. Sensor Integration

In modern vehicles, POF is integrated into sensors for measuring parameters like temperature, pressure, and strain. The fiber’s ability to withstand harsh automotive environments makes it suitable for these applications.

– Key Features:

– Immunity to electromagnetic interference (EMI), ensuring reliable sensor performance.

– High sensitivity for accurate measurements in dynamic conditions.

– Compact size enabling seamless integration into vehicle components.

Advantages of Using Plastic Optical Fiber in Automobiles

1. Weight Reduction: POF is significantly lighter than copper wiring, contributing to fuel efficiency and reduced emissions.

2. Cost-Effectiveness: Lower material costs and easier installation compared to traditional wiring systems.

3. Enhanced Performance: Reduced signal degradation and improved data transmission speeds.

4. Design Flexibility: The flexibility of POF allows for innovative design solutions in vehicle interiors and exteriors.

5. Durability: Resistant to environmental factors such as temperature fluctuations and vibrations, ensuring long-term reliability.

Challenges and Considerations

While plastic optical fiber offers numerous benefits, there are some challenges to consider:

– Signal Attenuation: Higher attenuation compared to glass fibers limits transmission distances.

– Bandwidth Limitations: POF has lower bandwidth capacity, making it suitable only for short-distance applications within vehicles.

– Installation Complexity: Requires specialized tools and techniques for optimal performance.

Conclusion

Plastic optical fiber is revolutionizing the automobile manufacturing industry by providing a lightweight, cost-effective, and high-performance alternative to traditional wiring systems. Its versatility across various applications makes it an essential component in modern vehicle design. As technology continues to evolve, POF will likely play an even more significant role in future automotive innovations.

References

1. [Optical Fiber Communication for Automotive Applications](https://example.com)

2. [Vehicle Networking with Plastic Optical Fibers](https://example.com)

3. [Applications of POF in Lighting Systems](https://example.com)