Introduction

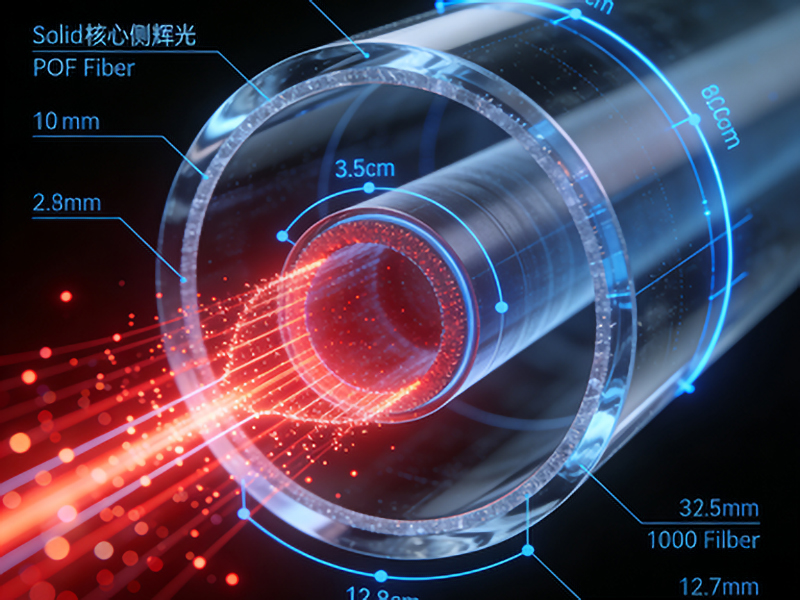

Plastic Optical Fibers (POF) have become a popular choice in various applications due to their flexibility, cost-effectiveness, and ease of handling compared to traditional glass fibers. At the heart of these fibers lies the optical transparent material that ensures efficient light transmission. This article delves into the types of materials used for POFs, their properties, and how they contribute to the performance of these fibers.

Types of Optical Transparent Materials Used in POF

The primary materials used for POF are polymers due to their flexibility and cost-effectiveness. The most common polymer materials include:

1. Polymethyl Methacrylate (PMMA)

– Properties: PMMA is a thermoplastic polymer known for its high transparency, excellent mechanical properties, and resistance to weathering.

– Transparency Range: Typically operates in the visible spectrum (400-700 nm) with high clarity.

– Application: Widely used in lighting applications and short-distance communication systems due to its balance of cost and performance.

2. Fluorinated Polymers

– Properties: These polymers, such as polyvinylidene fluoride (PVDF), offer improved transparency in the infrared spectrum and are highly resistant to environmental factors like UV radiation.

– Transparency Range: Effective in the near-infrared range (700-2500 nm).

– Application: Ideal for applications requiring data transmission over longer distances or in harsh environments.

3. Cyclo Olefin Copolymers (COC)

– Properties: COC materials are known for their excellent optical clarity, low birefringence, and high temperature resistance.

– Transparency Range: Offers good transparency across a broad spectrum, including UV and visible light.

– Application: Used in high-performance POFs where signal integrity is critical, such as in medical imaging or advanced telecommunications.

Key Technical Parameters for Optical Transparency

When evaluating optical transparent materials for POFs, several technical parameters are crucial:

1. Refractive Index (n)

– Definition: The refractive index measures how much light slows down when passing through the material compared to a vacuum.

– Importance: A higher refractive index enables better confinement of light within the fiber, reducing signal loss.

– Typical Values: PMMA has an n around 1.49, while fluorinated polymers can reach up to 1.75 depending on the specific polymer blend.

2. Attenuation Coefficient (α)

– Definition: This measures the reduction in light intensity as it travels through the fiber material.

– Importance: Lower attenuation coefficients mean less signal loss over distance, improving communication efficiency.

– Typical Values: Ranges from 0.1 dB/km to several hundred dB/km depending on the material and wavelength used.

3. Birefringence (Δn)

– Definition: The difference in refractive indices for light traveling in different directions within the material.

– Importance: Low birefringence reduces signal distortion, maintaining data integrity over longer distances.

– Typical Values: Aimed to be as low as possible, with COC materials achieving Δn values below 10^-4.

4. Temperature and Environmental Resistance

– Definition: The ability of the material to maintain its optical properties under varying temperature and environmental conditions.

– Importance: Ensures consistent performance in diverse operating environments, from industrial settings to outdoor installations.

Selection Considerations for Optical Transparent Materials

When selecting materials for POFs, several factors must be considered:

1. Operating Wavelength

– The desired wavelength range of light transmission determines the suitable material. For instance, PMMA is ideal for visible light, while fluorinated polymers excel in infrared applications.

2. Transmission Distance

– Longer transmission distances require materials with lower attenuation coefficients and higher refractive indices to minimize signal loss.

3. Environmental Conditions

– Materials must be chosen based on their resistance to UV radiation, temperature fluctuations, and moisture to ensure durability and performance longevity.

4. Cost and Availability

– Balancing cost-effectiveness with required performance is essential. PMMA offers a cost-effective solution for shorter-distance applications, while more advanced materials like COC are justified in high-performance scenarios.

Conclusion

The choice of optical transparent material significantly impacts the efficiency and application range of Plastic Optical Fibers. By understanding the properties, technical parameters, and selection considerations of these materials, engineers and designers can make informed decisions to optimize POF performance for various applications. As technology advances, innovative materials continue to emerge, promising even better performance in future POF solutions.