Introduction to Short-Range Data Transmission via Plastic Optical Fiber

Plastic Optical Fiber (POF) has emerged as a cost-effective and efficient solution for short-range data transmission in various industrial and commercial applications. Unlike traditional glass optical fibers, POF is made from high-quality plastic materials, making it more flexible, easier to install, and less expensive. This article delves into the technical aspects of POF-based data transmission, including its key advantages, challenges, and real-world applications.

What is Plastic Optical Fiber?

Plastic Optical Fiber (POF) is a type of optical fiber that uses plastic as the core material instead of glass. It is typically used for short-distance communication due to its higher attenuation compared to glass fibers. POF is widely adopted in environments where cost, flexibility, and ease of installation are critical factors.

Key Features of Plastic Optical Fiber:

– High Flexibility: The plastic material allows the fiber to bend easily without breaking or degrading performance.

– Ease of Use: Simpler termination and connection processes compared to glass fibers.

– Lower Cost: Cheaper manufacturing process makes it an economical choice for short-range applications.

– Good Bandwidth: Supports high-speed data transmission suitable for many industrial and consumer electronics needs.

Technical Parameters of POF-Based Data Transmission

When evaluating the performance of a POF-based system, several technical parameters are essential:

1. Attenuation

Attenuation refers to the reduction in signal strength as it travels through the fiber. For POF, typical attenuation is higher than glass fibers, usually ranging from 20 dB/km to 30 dB/km at common wavelengths like 850 nm. This makes POF unsuitable for long-distance applications but effective for short-range communication.

2. Bandwidth

The bandwidth of a fiber determines the maximum data rate it can support. For POF, typical bandwidths are in the range of 1 GHz·km to 10 GHz·km, which is sufficient for many industrial automation and consumer electronics applications requiring high-speed data transfer.

3. Connector Types

Commonly used connectors include:

– SC Connectors: Suitable for high-density applications with excellent performance.

– FC Connectors: Known for precision alignment, ideal for laboratory settings.

– ST Connectors: Easy to install and maintain, commonly used in industrial environments.

4. Operating Wavelengths

POF systems primarily operate at wavelengths of 650 nm (red light) and 850 nm (near-infrared). These wavelengths offer a good balance between cost, performance, and availability of compatible components.

Advantages of Using Plastic Optical Fiber for Short-Range Data Transmission

1. Cost-Effective: The manufacturing process is less expensive than glass fibers, making POF an attractive option for budget-conscious applications.

2. Flexibility: Easier to install in tight spaces and complex layouts without worrying about fiber breakage.

3. Immunity to Electromagnetic Interference (EMI): Unlike copper cables, POF is immune to EMI, ensuring reliable data transmission in electrically noisy environments.

4. Lightweight: The plastic material makes it lighter than glass fibers, reducing installation and maintenance efforts.

5. High Data Rates: Capable of supporting high-speed data transfer suitable for modern applications like industrial automation and multimedia systems.

Challenges and Limitations

Despite its advantages, POF-based data transmission also faces several challenges:

1. Higher Attenuation: Higher signal loss compared to glass fibers limits the effective transmission distance to short ranges (typically up to 50 meters).

2. Bandwidth Constraints: While sufficient for many applications, POF’s bandwidth is lower than that of glass fibers, limiting its use in high-performance networking environments.

3. Temperature Sensitivity: Some types of POF can be sensitive to temperature changes, affecting signal integrity under extreme conditions.

4. Limited Availability of Components: Compared to glass fiber systems, the range of compatible components and accessories for POF is more limited.

Applications of Short-Range Data Transmission via Plastic Optical Fiber

Plastic Optical Fiber is widely used in various sectors due to its unique advantages:

1. Industrial Automation: Used in factory floors for connecting sensors, actuators, and control systems, providing reliable and high-speed communication.

2. Consumer Electronics: Applied in devices like home theater systems, gaming consoles, and high-speed data transfer cables (e.g., HDMI over POF).

3. Medical Equipment: Utilized in medical imaging and diagnostic equipment where EMI immunity is crucial for patient safety.

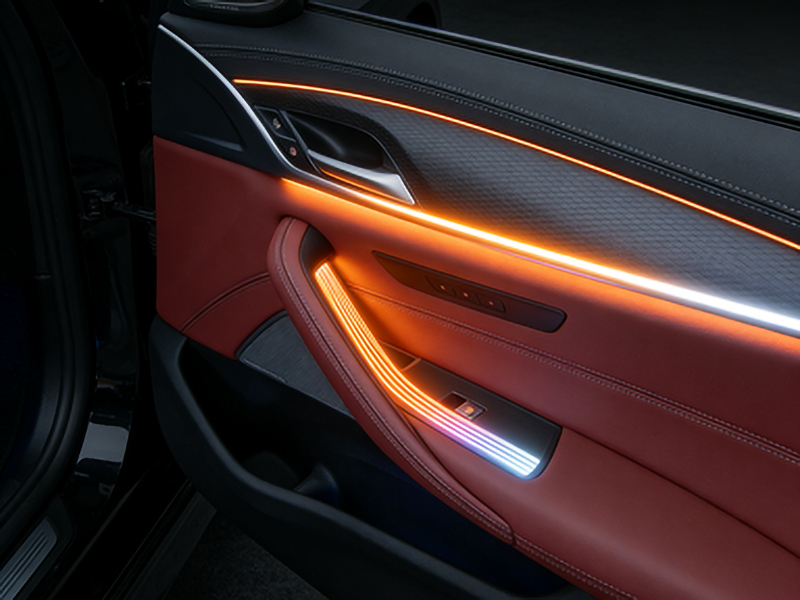

4. Automotive Industry: Employed in vehicles for data communication between different subsystems, enhancing performance and reliability.

5. Building Automation: Used in smart buildings for connecting lighting systems, security cameras, and environmental sensors.

Conclusion

Plastic Optical Fiber offers a robust solution for short-range data transmission, combining cost-effectiveness with high flexibility and EMI immunity. While it may not be suitable for long-distance applications due to higher attenuation, POF excels in environments where ease of installation, reliability, and affordability are key considerations. As technology advances, the adoption of POF is expected to grow across various industries, making it an essential component in modern data communication systems.