Introduction

Plastic Optical Fiber (POF) has emerged as a game-changer in the field of optical communication, offering a cost-effective and versatile alternative to traditional glass-based optical fibers. However, the conventional manufacturing methods for POF have posed challenges in achieving optimal performance and scalability. Enter low-intensity ultrasonic polymerization—a groundbreaking technique that is revolutionizing the way we produce high-quality plastic optical fibers.

Understanding Plastic Optical Fiber

Plastic Optical Fiber (POF) utilizes polymer materials such as polymethyl methacrylate (PMMA) or polystyrene to transmit light signals over short to medium distances. POFs are widely used in applications like data communication, sensors, and lighting due to their flexibility, ease of installation, and lower cost compared to glass fibers.

Key Characteristics of POF

– High transmission efficiency: Ensures minimal signal loss over the fiber length.

– Flexibility: Allows for easy routing in complex environments.

– Cost-effectiveness: Reduces overall system costs due to simpler manufacturing processes.

– Durability: Resistant to environmental factors, making them suitable for various industrial applications.

The Challenge of Conventional POF Manufacturing

Despite their advantages, traditional methods for manufacturing POF have inherent limitations. These include:

– High production costs: Due to the need for precise control over polymerization processes.

– Limited scalability: Difficulties in producing fibers with consistent quality at large scales.

– Complexity in achieving desired optical properties: Challenges in controlling fiber geometry and refractive index profiles.

Enter Low-Intensity Ultrasonic Polymerization

Low-intensity ultrasonic polymerization (LIUP) represents a significant leap forward in POF manufacturing. This technique employs low-intensity ultrasound to induce polymerization, offering numerous advantages over conventional methods.

How LIUP Works

The process involves subjecting the polymer precursor material to ultrasonic waves of low intensity. These waves create localized regions of high shear stress and temperature within the polymer solution, promoting controlled polymerization without inducing excessive heat that could degrade the material.

Key Parameters in LIUP

– Ultrasonic frequency: Typically ranges between 20 kHz to 1 MHz, depending on the polymer type and desired fiber properties.

– Power intensity: Maintained at low levels (一般在0.1至1瓦特每平方厘米之间) to ensure uniform polymerization without thermal damage.

– Polymer precursor concentration: Usually in the range of 5% to 20% by weight for optimal fiber formation.

– Fiber drawing speed: Varied based on the specific polymer and desired fiber diameter, typically between 10 mm/min to 50 mm/min.

Advantages of LIUP

– Cost-efficiency: Reduces energy consumption and minimizes material waste.

– Scalability: Enables consistent production of high-quality fibers at large scales.

– Enhanced optical properties: Allows for precise control over fiber geometry, improving light transmission efficiency.

– Environmentally friendly: Lower energy requirements result in a smaller carbon footprint compared to traditional methods.

Applications of POF Produced via LIUP

The improved characteristics of POF produced through low-intensity ultrasonic polymerization open up new possibilities across various industries:

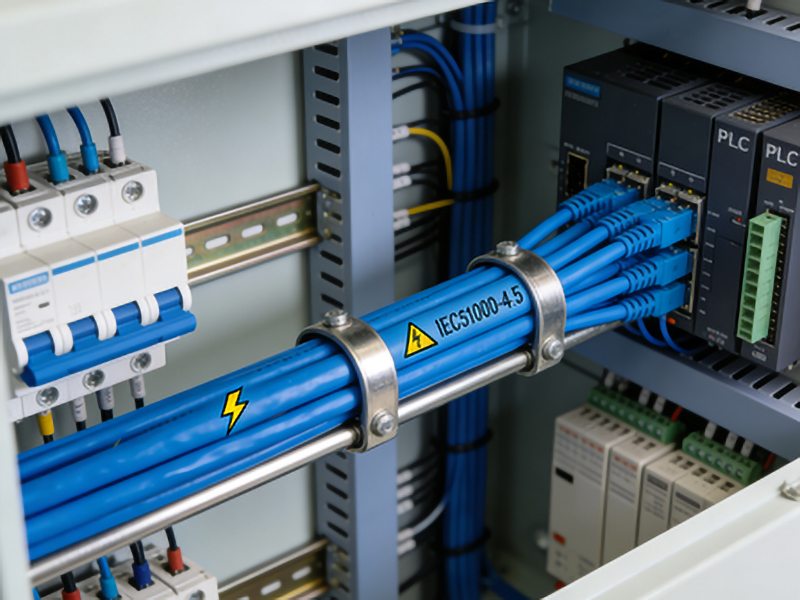

1. Telecommunications

Enhanced data transmission rates and reduced signal attenuation make these fibers ideal for high-speed communication networks, especially in short to medium-distance applications.

2. Sensing and Monitoring

The flexibility and durability of LIUP-produced POFs are well-suited for use in industrial sensors, environmental monitoring systems, and medical devices where reliable data transmission is critical.

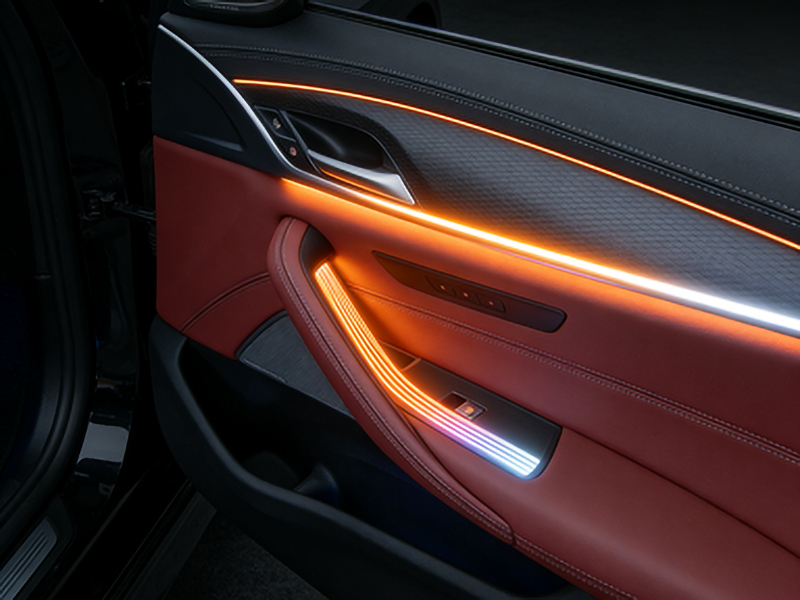

3. Lighting and Display Technologies

POFs produced via LIUP can efficiently transport light in lighting systems and optical displays, offering a combination of brightness, color fidelity, and energy efficiency.

Conclusion

Low-intensity ultrasonic polymerization is paving the way for a new era in plastic optical fiber manufacturing. By addressing the limitations of conventional methods, LIUP not only enhances the performance of POFs but also makes their production more cost-effective and scalable. As this technology continues to evolve, it holds immense potential to transform various sectors reliant on optical communication systems.