Introduction

Plastic Optical Fiber (POF) has emerged as a cost-effective and versatile solution in the field of optical communications. However, challenges such as sensitivity to vibrations and susceptibility to cracking have hindered its widespread adoption. This article delves into the innovations that make POF vibration and crack-resistant, discussing their technical specifications, applications, and benefits.

Technical Specifications

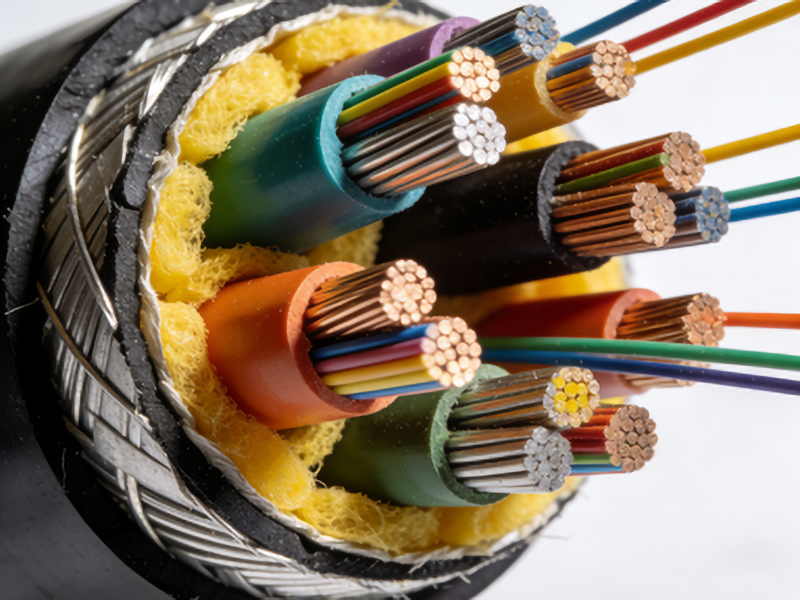

Vibration and crack-resistant POFs are engineered with advanced materials and manufacturing techniques. Key parameters include:

– Outer Diameter (OD): Typically ranges from 0.5 to 1 mm, ensuring compatibility with standard connectors.

– Cladding Thickness: Varies between 50 μm to 200 μm, enhancing durability without compromising light transmission efficiency.

– Tensile Strength: Exceeds 40 MPa, providing robustness against mechanical stress.

– Operating Temperature Range: Designed to function reliably from -40°C to +85°C, making them suitable for diverse environmental conditions.

– Flexibility Radius: Can bend up to a radius of 25 mm without performance degradation, ideal for complex installations.

Manufacturing Process

The production of vibration and crack-resistant POF involves several critical steps:

1. Material Selection: High-quality polymers, such as PMMA (Polymethyl Methacrylate), are chosen for their optical clarity and mechanical strength.

2. Extrusion: The raw polymer is heated and extruded through precision dies to achieve the desired fiber dimensions.

3. Cladding Application: A protective layer is applied to enhance durability and prevent signal loss due to external factors.

4. Cooling and Annealing: Controlled cooling ensures minimal residual stress, while annealing improves the fiber’s mechanical properties.

5. Testing: Each batch undergoes rigorous testing for tensile strength, flexibility, and optical performance.

Applications

These advanced POFs find application in various sectors:

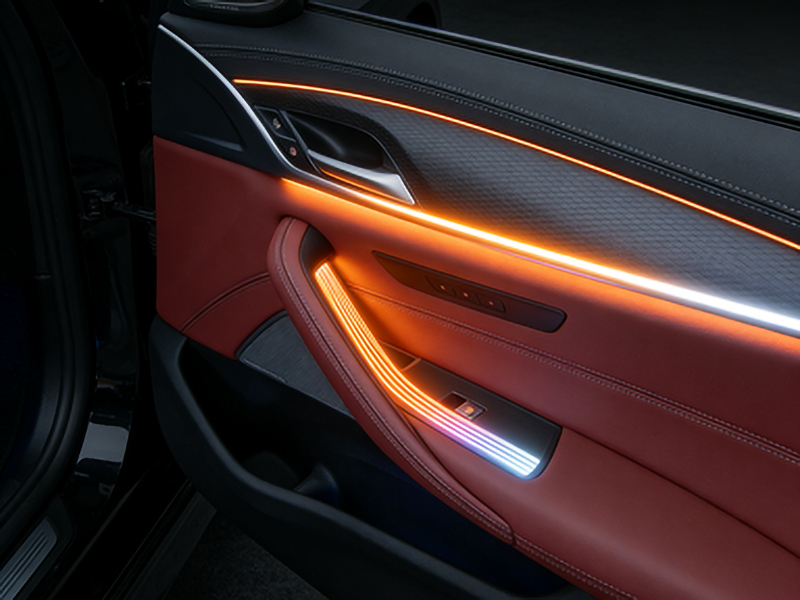

– Automotive Industry: Used in vehicle data buses to transmit signals between different components.

– Telecommunications: Ideal for short-distance communication within buildings or campuses.

– Industrial Automation: Facilitates reliable data transmission in harsh industrial environments.

– Medical Equipment: Employed in medical devices where flexibility and durability are crucial.

Benefits

The adoption of vibration and crack-resistant POF offers numerous advantages:

1. Cost Efficiency: Lower production costs compared to traditional glass fibers make them an attractive option for budget-conscious projects.

2. Ease of Installation: Flexible design allows for easy routing through tight spaces without the risk of signal loss.

3. Durability: Enhanced resistance to environmental factors extends the lifespan of the fiber, reducing maintenance needs.

4. Lightweight Design: Reduced weight compared to glass fibers makes them ideal for applications where portability is a concern.

Challenges and Future Directions

Despite their advantages, vibration and crack-resistant POFs face challenges such as limited bandwidth compared to glass fibers. Ongoing research focuses on improving signal integrity and expanding their applicability in high-speed communication systems. The integration of advanced materials and nanotechnology holds promise for overcoming these limitations.

Conclusion

Vibration and crack-resistant plastic optical fibers represent a significant advancement in optical communication technology. Their unique properties make them suitable for a wide range of applications, from automotive systems to medical equipment. As technology continues to evolve, these fibers are expected to play an increasingly important role in the telecommunications industry, offering reliable and cost-effective solutions for modern communication needs.