As the largest plastic optical fiber manufacturer in China and a leader in optical fiber applications. They adopt a series of high-precision technologies and processes to ensure that every optical fiber meets the standards. Below are the key steps of plastic optical fiber manufacturing:

1. Raw Material Selection and Preparation

The production of plastic optical fibers starts with high-quality polymer raw materials, the commonly used materia is poly methyl methacrylate (PMMA)l.

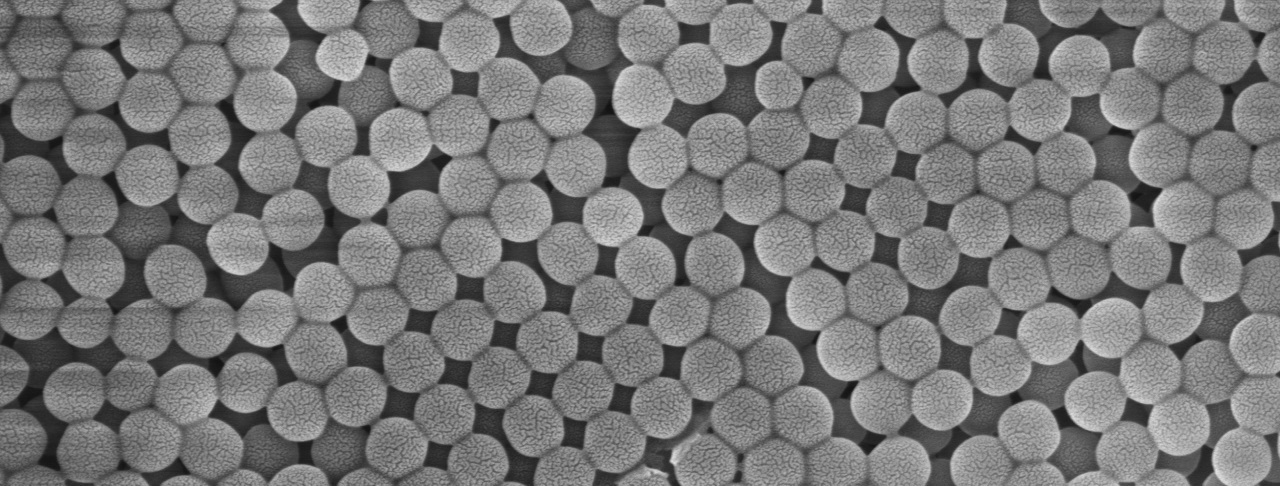

Jiangxi Daishing strictly selects high-quality PMMA particles to ensure excellent transparency and optical performance. Through meticulous screening and pretreatment of raw materials, the optical quality during subsequent production processes is guaranteed.

2. Extrusion forming

In the manufacturing process of plastic optical fibers, extrusion forming is the most critical step. Jiangxi Daishing uses advanced extrusion equipment to heat the pre-treated PMMA particles to a molten state and extrude them into shape through specific molds. At this point, the core and cladding of the fiber (i.e. the inner and outer layers of the fiber) begin to take shape. The core part is usually made of transparent polymethyl methacrylate, while the outer cladding layer is made of materials such as polyvinyl chloride (PVC) to improve the durability and environmental resistance of the optical fiber.

3. Plastic Optical Fiber stretching

After extrusion forming, the plastic optical fiber enters the stretching stage. By high-speed stretching, the diameter of the optical fiber is precisely controlled, while ensuring that the internal structure of the fiber is optimized to effectively transmit optical signals. Jiangxi Daishing adopts an automated stretching control system to ensure that the plastic optical fiber maintains consistent optical performance and physical strength during the stretching process.

4. Plastic optical fiber coating and curing

Coating and curing are essential steps to enhance the mechanical strength and protective performance of plastic optical fibers. During this process, the surface of the optical fiber will be coated with a special coating material. This coating not only protects the optical fiber from external environmental influences, but also improves its durability and working life.

5. Quality control and testing

Quality control is a crucial part of the manufacturing process of Jiangxi Daishing Plastic Optical Fiber. After production, each fiber optic cable undergoes rigorous testing and inspection, including:

Optical performance testing: Ensure that optical parameters such as transmission speed, loss, and signal attenuation of optical fibers meet relevant standards.

Physical performance testing: including the tensile strength, temperature resistance, and chemical corrosion resistance of optical fibers to ensure their stability in various usage environments.

Appearance inspection: Ensure that the surface of the optical fiber is smooth and uniform, and avoid defects such as bubbles and cracks that may affect performance.

6. Packaging and shipping

After strict quality inspection, plastic optical fibers that meet the standards will be wound into reels and packaged according to customer needs. Jiangxi Daishing also attaches great importance to the packaging process, using moisture-proof and dust-proof materials to ensure that optical fibers are not damaged during transportation and storage.

Jiangxi Daishing POF Co., Ltd., as a national high-tech enterprise, has become a leader in the global plastic fiber optic industry with its exquisite manufacturing technology, strict quality control, and continuous technological innovation. From raw material selection to finished product shipment, every fiber optic cable undergoes strict scrutiny to ensure its stable operation in various complex application environments. With the continuous growth of demand for plastic optical fibers, Jiangxi Daishing will continue to provide high-quality plastic optical fiber products to global customers, promoting the rapid development of the industry.