Plastic optical fiber: The “Invisible Hero” in the Era of Industry 4.0

When it comes to Industry 4.0, people may first think of high-end concepts such as robots, the Internet of Things and big data. But do you know that behind these cool technologies, there is something seemingly ordinary yet crucial that quietly supports the entire system – that is plastic optical fiber.

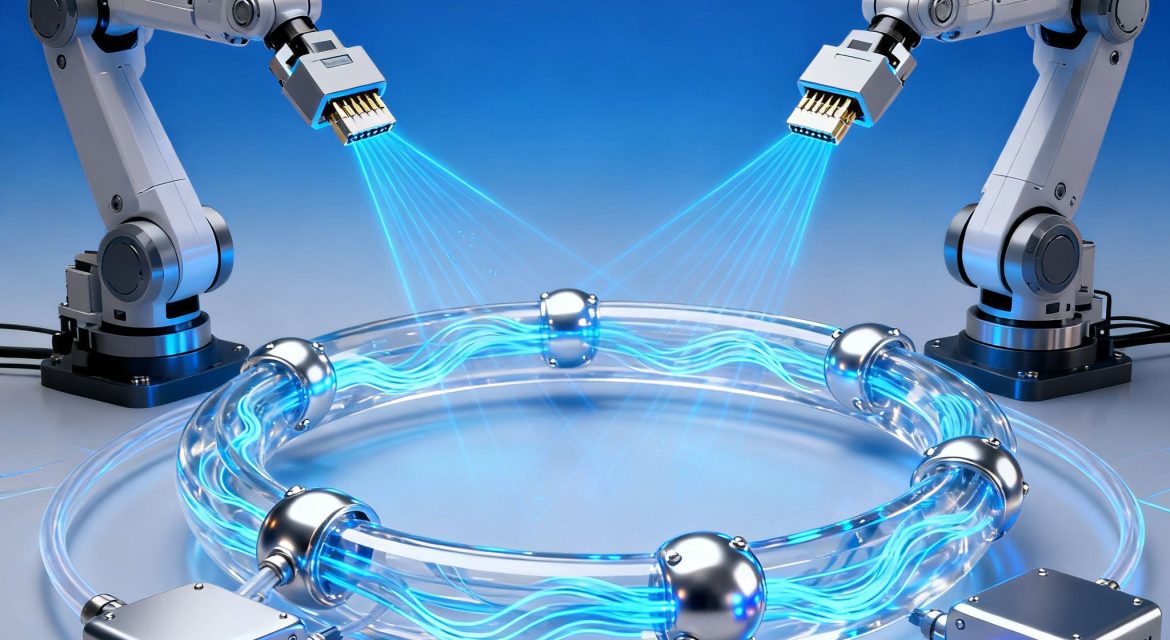

Plastic optical fibers are quite different from the glass optical fibers we usually talk about. It is cheaper, softer and easier to install, and is particularly suitable for those occasions in factories where frequent movement and bending are required. Imagine that on an automated production line, robot arms need to keep rotating and sensors need to transmit data in real time. At this point, the advantages of plastic optical fibers come into play.

In smart factories, plastic optical fibers are like the neural networks of the human body. It connects various devices, enabling data to flow rapidly. For instance, the working status of an injection molding machine, the temperature reading of a sensor, and the image information of a camera all need to be transmitted in real time to the control center via optical fiber networks. Without this “neural network”, even the most intelligent devices are just isolated individuals and cannot form an intelligent system that works collaboratively.

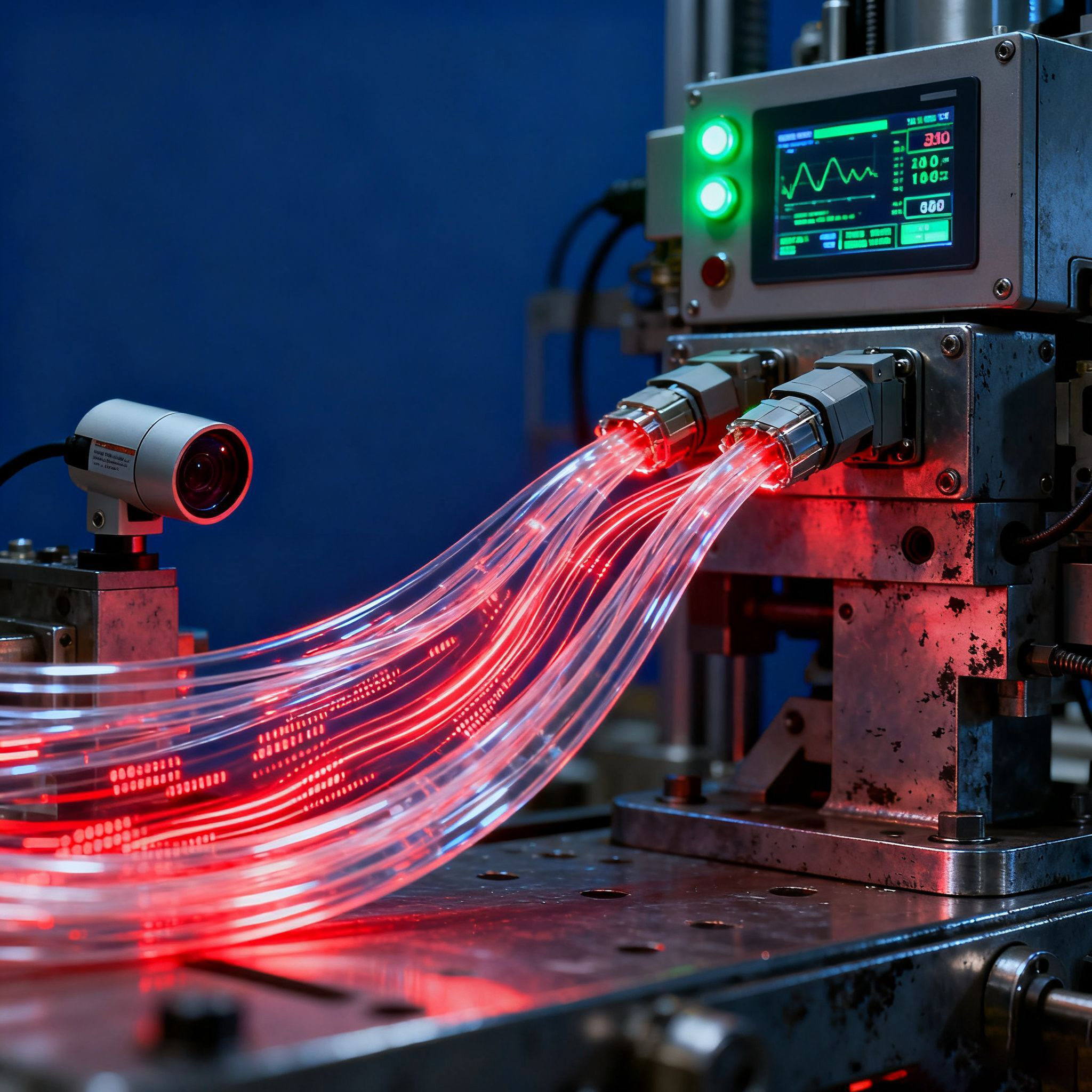

Plastic optical fibers have another significant advantage – they are resistant to electromagnetic interference. The factory is filled with devices such as motors and frequency converters that can generate electromagnetic interference. If ordinary cables are used, the signals are very likely to be interfered with. Plastic optical fibers are completely unaffected by electromagnetic fields and can ensure the stability and reliability of data transmission. This is particularly important for industrial environments that require high precision.

With the development of the industrial Internet of Things, more and more devices need to be connected in factories. From traditional production equipment to various sensors and actuators, and then to AGV carts and intelligent warehousing systems, all require reliable communication networks. Plastic optical fibers not only have a low cost but also have a large enough bandwidth to fully meet the communication requirements of these devices.

However, plastic optical fibers are not omnipotent. Its transmission distance is relatively short, generally within 100 meters, which limits its application in large factories. But within the scope of a workshop or a production line, it is definitely the choice with the best cost performance.

In the future, with the in-depth development of Industry 4.0, the application of plastic optical fibers will be even more extensive. For instance, in explosion-proof chemical workshops, in damp food processing plants, and inside equipment with limited space, plastic optical fibers can all find their application. It may not be as eye-catching as a robot, but it is indeed an indispensable infrastructure for Industry 4.0.

The next time you see a promotional video for an intelligent factory, don’t forget to think about it – behind those smoothly running devices, there might be bundles of plastic optical fibers silently transmitting data, just like the blood vessels in the human body. Although they are invisible, they are of vital importance. This is the “invisible hero” of the Industry 4.0 era, supporting the most cutting-edge technologies in the most down-to-earth way.